Allen AW16 Wheel Buggy and Dumper Parts

SEARCH Allen AW16 Wheel Buggy and Dumper Parts

RESULT

-

Original price $107.27 - Original price $107.27Original price$107.27$107.27 - $107.27Current price $107.27| /

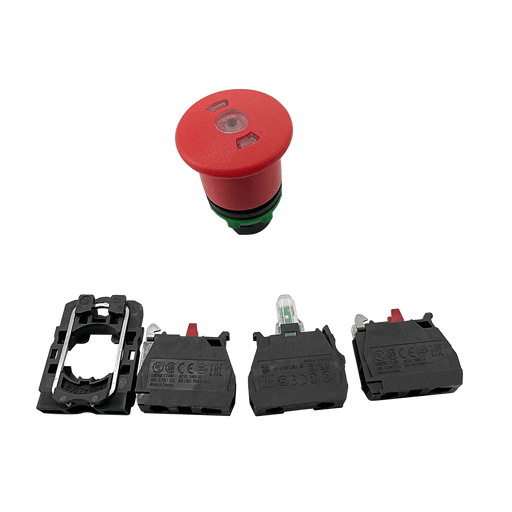

Skyjack Platform E-St Switch Assembly 144647

SkyjackIn stockDescriptionThe Skyjack Switch 144647 is a must-have for your machine. Its weight is 0.2 lbs. It is constructed with robust materials to provide a l...

View full detailsOriginal price $107.27 - Original price $107.27Original price$107.27$107.27 - $107.27Current price $107.27| /

Can't find the part you're looking for?

Can't find the part you're looking for?

CALL US: 573-355-6493

EMAIL US: shop@equipmentshare.com

Can't find the part you're looking for?

Allen AW16 Parts

Shop our catalog of Allen AW16 parts to find the parts you need to keep your machines running smoothly.

Popular Models

Sany SY215C Excavator Parts

Sany SY135C Compact Excavator Parts

Takeuchi TL8R2 Compact Track Loader Parts

Takeuchi TL12R2 Compact Track Loader Parts

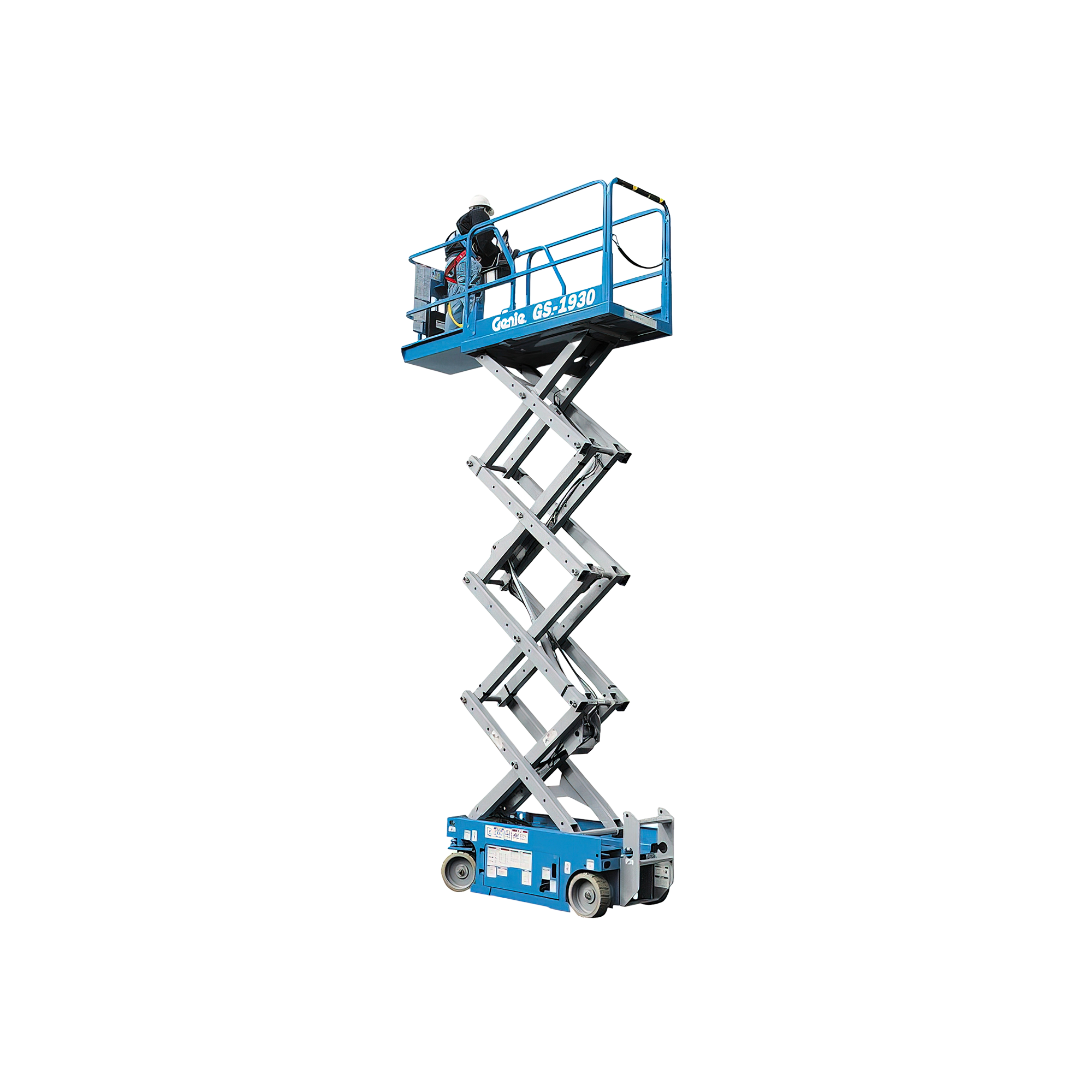

Genie GS-1930 Electric Scissor Lift Parts

Genie GS-2632 Electric Scissor Lift Parts

Skyjack SJIII 3219 Electric Scissor Lift Parts

MEC Micro 19 Electric Scissor Lift Parts

Genie GTH-5519 Telehandler Parts