Allmand NLV3GR Towable Light Tower Parts

SEARCH Allmand NLV3GR Towable Light Tower Parts

RESULT

-

Original price $9.68 - Original price $9.68Original price$9.68$9.68 - $9.68Current price $9.68| /

Takeuchi Oil Filter 1990197066

TakeuchiIn stockDescriptionThe Takeuchi Oil Filter 1990197066 is designed for maximum performance and durability. It has a weight of 1.1 lbs. The filter’s robust c...

View full detailsOriginal price $9.68 - Original price $9.68Original price$9.68$9.68 - $9.68Current price $9.68| / -

Original price $8.48 - Original price $8.48Original price$8.48$8.48 - $8.48Current price $8.48| /

Baldwin Oil Filter B161-S

BaldwinIn stockKeep your engine running smoothly with the Baldwin B161-S oil filter. Built to trap dirt, metal shavings, and other harmful particles, this filter ...

View full detailsOriginal price $8.48 - Original price $8.48Original price$8.48$8.48 - $8.48Current price $8.48| / -

Original price $78.09 - Original price $78.09Original price$78.09$78.09 - $78.09Current price $78.09| /

Wacker Neuson Jack-Swivel, 2000# 5100036814

Wacker NeusonOut of stockDescriptionThe Wacker Neuson Swivel Jack 5100036814 is the perfect solution for hauling materials and towing machines on your worksite. Its weight ...

View full detailsOriginal price $78.09 - Original price $78.09Original price$78.09$78.09 - $78.09Current price $78.09| /Sold out -

Original price $161.77 - Original price $161.77Original price$161.77$161.77 - $161.77Current price $161.77| /

Takeuchi Pump, Fuel Feed Y119225-52102

TakeuchiIn stockDescriptionThe Takeuchi Pump Y119225-52102 is the perfect addition to ensure consistent liquid flow in your machine. It has a weight of 0.8 lbs. Ha...

View full detailsOriginal price $161.77 - Original price $161.77Original price$161.77$161.77 - $161.77Current price $161.77| / -

Original price $25.70 - Original price $25.70Original price$25.70$25.70 - $25.70Current price $25.70| /

Yanmar Element, Air Cleaner 114250-12581

YanmarLow stockDescriptionThe Yanmar Air Filter 114250-12581 prevents dust and other harmful particles from entering your engine which can create a number of prob...

View full detailsOriginal price $25.70 - Original price $25.70Original price$25.70$25.70 - $25.70Current price $25.70| / -

Original price $10.25 - Original price $10.25Original price$10.25$10.25 - $10.25Current price $10.25| /

Baldwin Fuel Filter PF937

BaldwinIn stockDescription The Baldwin Fuel Filter PF937 is essential for keeping your machine running at peak efficiency. Designed to remove particles and contam...

View full detailsOriginal price $10.25 - Original price $10.25Original price$10.25$10.25 - $10.25Current price $10.25| / -

Original price $420.90 - Original price $420.90Original price$420.90$420.90 - $420.90Current price $420.90| /

Yanmar Starter Assembly, D 114362-77011

YanmarOut of stockDescriptionThe Yanmar Starter 114362-77011 is the perfect choice for your machine. It has a weight of 8.3 lbs. Having a reliable starter is crucial...

View full detailsOriginal price $420.90 - Original price $420.90Original price$420.90$420.90 - $420.90Current price $420.90| /Sold out -

Original price $179.99 - Original price $179.99Original price$179.99$179.99 - $179.99Current price $179.99| /

Yanmar Regulator Assembly 114399-77551

YanmarOut of stockManufacturer: Yanmar Part Name: Regulator Assembly Part Number/MPN: 114399-77551

Original price $179.99 - Original price $179.99Original price$179.99$179.99 - $179.99Current price $179.99| /Sold out -

Original price $8.04 - Original price $8.04Original price$8.04$8.04 - $8.04Current price $8.04| /

Baldwin Heavy Duty Lube Spin-On Filter B179

BaldwinOut of stockManufacturer: Baldwin Part Name: Heavy Duty Lube Spin-On Filter Part Number/MPN: B179

Original price $8.04 - Original price $8.04Original price$8.04$8.04 - $8.04Current price $8.04| /Sold out -

Original price $10.56 - Original price $10.56Original price$10.56$10.56 - $10.56Current price $10.56| /

NAPA Fuel Filter 3262

NAPALow stockManufacturer: NAPA Part Name: Fuel Filter Part Number/MPN: 3262

Original price $10.56 - Original price $10.56Original price$10.56$10.56 - $10.56Current price $10.56| / -

Original price $5.90 - Original price $5.90Original price$5.90$5.90 - $5.90Current price $5.90| /

Yanmar Foam For Air Filter 114250-12580F

YanmarIn stockDescriptionThe Yanmar Foam 114250-12580F is a fantastic choice for any project. Its weight is 0.0 lbs. Providing solid insulation on your equipment...

View full detailsOriginal price $5.90 - Original price $5.90Original price$5.90$5.90 - $5.90Current price $5.90| / -

Original price $25.15 - Original price $25.15Original price$25.15$25.15 - $25.15Current price $25.15| /

Wacker Neuson Hitch 5000164599

Wacker NeusonOut of stockDescriptionThe Wacker Neuson Hitch 5000164599 is a must-have for any machine. Its weight is 4.7 lbs. Made from durable materials, you can count on ...

View full detailsOriginal price $25.15 - Original price $25.15Original price$25.15$25.15 - $25.15Current price $25.15| /Sold out -

Original price $6.10 - Original price $6.10Original price$6.10$6.10 - $6.10Current price $6.10| /

Wix Oil Filter 51334

WixOut of stockDescriptionThe Wix Oil Filter 51334 is designed for maximum performance and durability. It has a weight of 1.1 lbs. The filter’s robust constructio...

View full detailsOriginal price $6.10 - Original price $6.10Original price$6.10$6.10 - $6.10Current price $6.10| /Sold out -

Original price $11.07 - Original price $11.07Original price$11.07$11.07 - $11.07Current price $11.07| /

Yanmar Filter Assembly, D80X80L 129150-35153

YanmarIn stockDescriptionThe Yanmar Filter 129150-35153 is designed to keep your machine running smoothly and efficiently. It has a weight of 0.8 lbs. It offers ...

View full detailsOriginal price $11.07 - Original price $11.07Original price$11.07$11.07 - $11.07Current price $11.07| / -

Original price $12.32 - Original price $12.32Original price$12.32$12.32 - $12.32Current price $12.32| /

Baldwin Air Filter PA4824

BaldwinIn stockDescriptionThe Baldwin Air Filter PA4824 prevents dust and other harmful particles from entering your engine which can create a number of problems....

View full detailsOriginal price $12.32 - Original price $12.32Original price$12.32$12.32 - $12.32Current price $12.32| /

Keeping your Allmand NLV3GR in peak operating condition starts with the right parts and a solid maintenance routine. Ensure your light tower stays in top shape with high-quality oil filters, swivels, pumps, and more. The NLV3GR features a robust diesel engine, high-output LED lighting, and the DSE L401 MKII controller for automated light scheduling, making it perfect for construction sites, emergency response, and industrial lighting. Don’t forget to stay on top of your maintenance—secure the parts you need to keep your Allmand NLV3GR running smoothly!

Walk-Around Inspection

- Inspect light tower mast and cables for visible wear or fraying

- Check that overhead clearance is available before raising the mast

- Inspect fluid levels: engine oil, coolant, diesel fuel, and DEF (if equipped)

- Verify battery terminals are clean and securely connected

- Check for fuel, coolant, or oil leaks around engine and hydraulics

- Ensure safety decals, reflectors, and covers are in place and legible

Daily Maintenance

- Check and top off engine oil and coolant levels

- Drain water separator from the fuel system

- Inspect radiator and intake screens for debris

- Test emergency stop, auto mode, and manual start functionality

- Inspect all lighting heads for functionality and secure mounting

Every 250 Hours

- Inspect and clean air cleaner restriction indicator

- Check radiator fins and fuel system for sediment or clogging

- Test control panel for display accuracy and button responsiveness

Every 500 Hours

- Change engine oil and oil filter

- Replace primary and secondary fuel filters

- Clean battery terminals and secure cables

Every 1,000 Hours

- Inspect and adjust drive belts and pulleys

- Inspect exhaust and muffler system for leaks or loose fittings

- Verify mast winch operation and cable condition

Every 2,000 Hours

- Replace coolant according to engine manufacturer schedule

- Replace air cleaner element and inspect housing

- Check all controller connections and electrical relays

Annual Maintenance

- Test light scheduling via DSE controller (start time, duration, sunrise/sunset modes)

- Lubricate mast pulleys, hinge points, and winch cable if applicable

- Inspect all LED fixtures and replace damaged lenses or mounts

As-Needed Maintenance

- Use controller to identify SPN/FMI diagnostic codes

- Clear fault codes using Stop/Reset button on controller

- Replace worn belts, cracked hoses, or malfunctioning switches

- Update firmware if controller version is outdated

Final Maintenance Recommendations

Regular maintenance keeps your Allmand NLV3GR operating safely and efficiently. For a full range of Allmand parts, explore our extensive EquipmentShare parts catalog. If you can’t find the part you need, reach out to our parts experts for a custom order.

Popular Models

Sany SY215C Excavator Parts

Sany SY135C Compact Excavator Parts

Takeuchi TL8R2 Compact Track Loader Parts

Takeuchi TL12R2 Compact Track Loader Parts

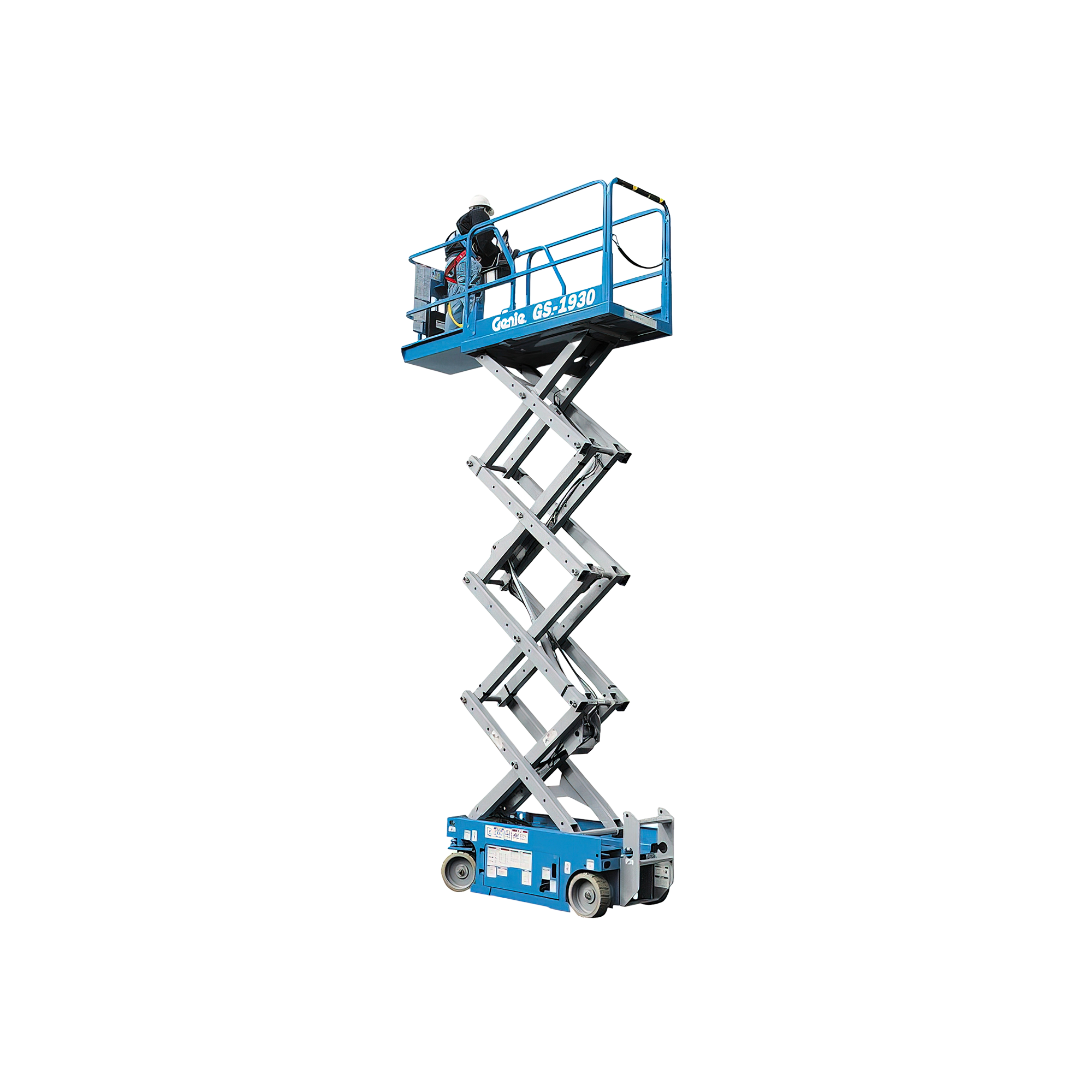

Genie GS-1930 Electric Scissor Lift Parts

Genie GS-2632 Electric Scissor Lift Parts

Skyjack SJIII 3219 Electric Scissor Lift Parts

MEC Micro 19 Electric Scissor Lift Parts

Genie GTH-5519 Telehandler Parts