Atlas Copco PAC F88 Centrifugal Pump Parts

SEARCH Atlas Copco PAC F88 Centrifugal Pump Parts

RESULT

-

Original price $593.76 - Original price $593.76Original price$593.76$593.76 - $593.76Current price $593.76| /

Atlas Copco 500 Hour Service Kit 1310076039

Atlas CopcoIn stockDescriptionThe Atlas Copco Filter Kit 1310076039 is designed to provide protection from dust, debris and other materials from slowing down your mac...

View full detailsOriginal price $593.76 - Original price $593.76Original price$593.76$593.76 - $593.76Current price $593.76| /

Keeping your Atlas Copco PAC F88 in peak operating condition starts with the right parts and a solid maintenance routine. Ensure your centrifugal pump stays in top shape with high-quality 500-hour service kits and more. Designed for demanding dewatering applications, the PAC F88 delivers high-flow performance and reliability, powered by a 120 HP Perkins T4F diesel engine. Don’t forget to stay on top of your maintenance—secure the parts you need to keep your Atlas Copco PAC F88 running smoothly!

Walk-Around Inspection

- Check suction and discharge hose connections for leaks or misalignment

- Inspect for fluid leaks around the mechanical seal, vacuum pump, and engine

- Verify battery terminals are clean and secure

- Inspect V-belts for tension, wear, and alignment

- Ensure access doors are closed and cooling inlets/outlets are clear

- Check levels of fuel, coolant, vacuum pump oil, and mechanical seal oil

Daily Maintenance

- Check engine oil and coolant levels

- Check vacuum pump oil and mechanical seal oil levels

- Inspect hoses and clamps for damage or leaks

- Drain water from condensate catch basin, if equipped

- Ensure the emergency stop is functional

- Verify control panel for alarms or fault codes

Every 250 Hours

- Replace engine oil and engine oil filter

- Replace vacuum pump oil and mechanical seal oil

- Inspect and clean battery terminals and check electrolyte level

- Inspect wear ring, impeller, and check valve for wear or blockage

- Check alternator belt tension

Every 500 Hours

- Replace air filter and fuel filter elements

- Inspect and tension vacuum pump belt or replace if worn

- Replace coolant if needed (based on condition)

- Inspect the rubber coupling and bearings for wear

- Clean radiator and inter cooler assemblies

Every 1000 Hours

- Replace V-belts and inspect pulley alignment

- Flush and refill coolant system

- Clean and inspect separator components and shaft bearings

Every 3000 Hours

- Replace pump shaft bearings

- Inspect and clean check valve and all internal pump components

- Replace engine coolant and inspect exhaust after-treatment components

Annually

- Perform complete inspection of all mechanical seals and vacuum diaphragm

- Test and verify function of all safety shutdowns (low oil, high temp, overspeed)

- Check tightness of all bolts and torque fasteners as specified

Every 2 Years

- Replace rubber hoses (fuel, coolant, intake) and vacuum diaphragm

- Flush and clean fuel tank and all fuel lines

As-Needed Maintenance

- Inspect and clean suction strainer to prevent clogging

- Inspect separator valve and float for correct function

- Lubricate all locks, hinges, and moving mechanical parts

- Replace worn impellers or damaged components as needed

Final Maintenance Recommendations

Regular maintenance keeps your Atlas Copco PAC F88 operating safely and efficiently. For a full range of Atlas Copco pump parts, explore our extensive EquipmentShare parts catalog. If you can’t find the part you need, reach out to our parts experts for a custom order.

Popular Models

Sany SY215C Excavator Parts

Sany SY135C Compact Excavator Parts

Takeuchi TL8R2 Compact Track Loader Parts

Takeuchi TL12R2 Compact Track Loader Parts

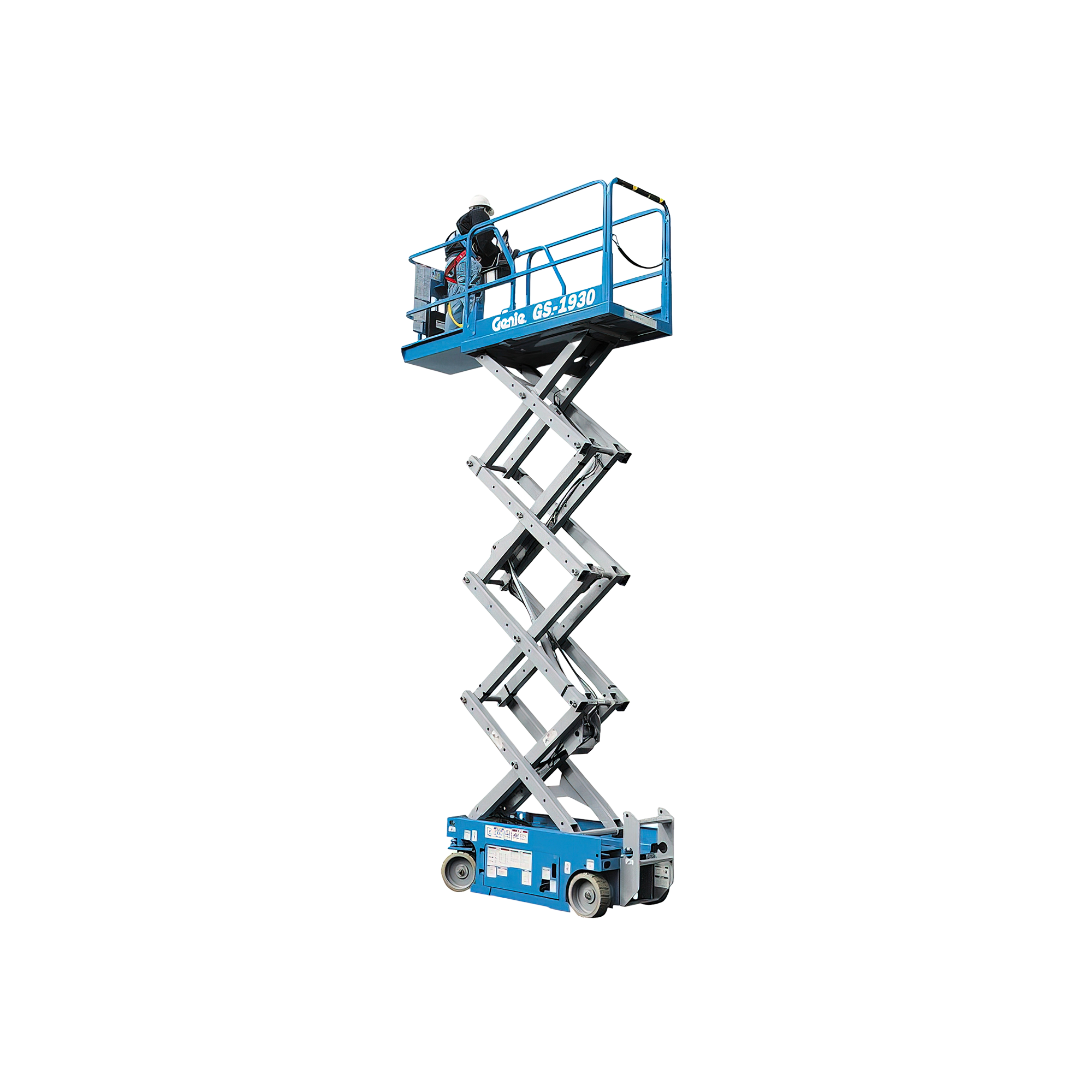

Genie GS-1930 Electric Scissor Lift Parts

Genie GS-2632 Electric Scissor Lift Parts

Skyjack SJIII 3219 Electric Scissor Lift Parts

MEC Micro 19 Electric Scissor Lift Parts

Genie GTH-5519 Telehandler Parts