CASE 588H Rough Terrain Forklift Parts

SEARCH CASE 588H Rough Terrain Forklift Parts

RESULT

-

Original price $34.48 - Original price $34.48Original price$34.48$34.48 - $34.48Current price $34.48| /

Baldwin Air Filter Element RS3544

BaldwinLow stockDescription The Baldwin Air Filter Element RS3544 is the perfect solution to keep your machine's engine free of any dust and harmful particles. A d...

View full detailsOriginal price $34.48 - Original price $34.48Original price$34.48$34.48 - $34.48Current price $34.48| / -

Original price $29.00 - Original price $29.00Original price$29.00$29.00 - $29.00Current price $29.00| /

Baldwin Filter BF7954-D

BaldwinIn stockManufacturer: Baldwin Part Name: Filter Part Number/MPN: BF7954-D

Original price $29.00 - Original price $29.00Original price$29.00$29.00 - $29.00Current price $29.00| / -

Original price $25.06 - Original price $25.06Original price$25.06$25.06 - $25.06Current price $25.06| /

Baldwin Fuel Filter BF7940

BaldwinIn stockManufacturer: Baldwin Part Name: Fuel Filter Part Number/MPN: BF7940

Original price $25.06 - Original price $25.06Original price$25.06$25.06 - $25.06Current price $25.06| /

Keeping your CASE 588H in peak operating condition starts with the right parts and a solid maintenance routine. Ensure your rough terrain forklift stays in top shape with high-quality filters, fuel filters, {part 3}, and more. The CASE 588H is built for heavy-duty lifting and material handling in demanding environments. Don’t forget to stay on top of your maintenance—secure the parts you need to keep your CASE 588H running smoothly! Keep reading for a comprehensive maintenance guide for your machine.

Walk-Around Inspection

Before operating your CASE 588H, perform a thorough walk-around inspection to prevent costly downtime and ensure operator safety. Regular inspections help identify issues early, allowing your forklift to operate efficiently. Key areas to focus on include:

- Check hydraulic fluid levels and inspect hoses for leaks or damage.

- Inspect tires for proper inflation, tread wear, and visible damage.

- Ensure all safety decals and warning labels are intact and legible.

- Verify that the forks, mast, and carriage rollers are secure and free from excessive wear.

Daily Maintenance

- Check engine oil level and top off if necessary.

- Inspect coolant level and transmission fluid.

- Check hydraulic reservoir fluid level.

- Test the parking brake and service brakes for proper operation.

- Lubricate mast pivot points and chain rollers.

50-Hour Maintenance

- Drain water from the fuel separator.

- Check hydraulic system for leaks and wear.

- Lubricate rear steer axle grease fittings.

100-Hour Maintenance

- Replace hydraulic filter.

- Inspect and adjust mast chains.

- Check and service brakes.

250-Hour Maintenance

- Inspect and clean battery terminals.

- Check rear steer axle and front drive axle oil levels.

- Inspect transmission oil and fuel system.

500-Hour Maintenance

- Change engine oil and replace oil filter.

- Inspect and adjust forklift mast chains.

- Lubricate all grease fittings, including tilt cylinders.

1,000-Hour Maintenance

- Flush and replace hydraulic fluid.

- Replace transmission oil and filter.

- Inspect and replace worn hydraulic hoses.

Final Maintenance Recommendations

Regular maintenance keeps your CASE 588H operating reliably. For a full range of CASE parts, explore our extensive EquipmentShare parts catalog. If you can't find the part you need, reach out to our parts experts for a custom order.

Popular Models

Sany SY215C Excavator Parts

Sany SY135C Compact Excavator Parts

Takeuchi TL8R2 Compact Track Loader Parts

Takeuchi TL12R2 Compact Track Loader Parts

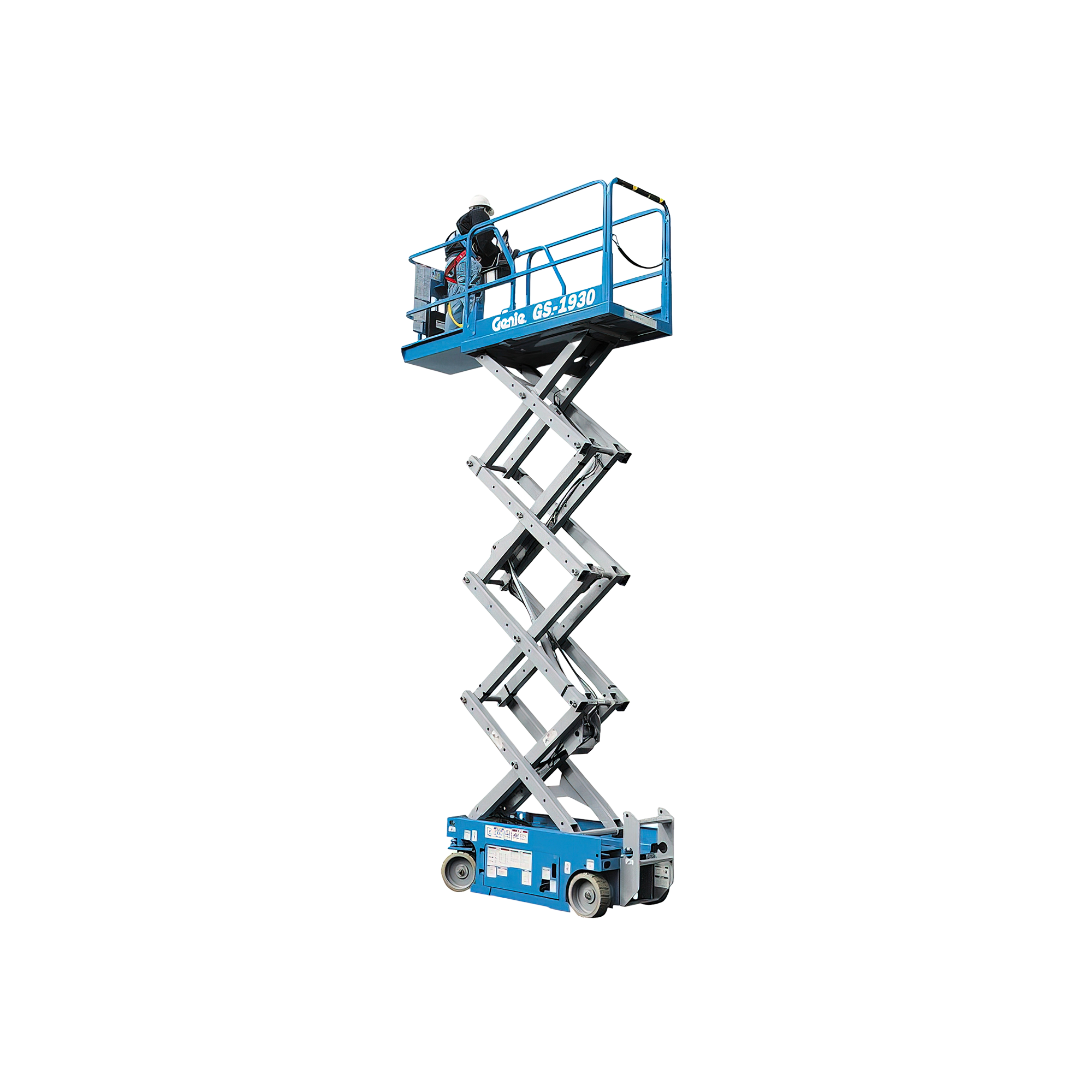

Genie GS-1930 Electric Scissor Lift Parts

Genie GS-2632 Electric Scissor Lift Parts

Skyjack SJIII 3219 Electric Scissor Lift Parts

MEC Micro 19 Electric Scissor Lift Parts

Genie GTH-5519 Telehandler Parts