Ditch Witch RT45A Ride-On Trencher Parts

SEARCH Ditch Witch RT45A Ride-On Trencher Parts

RESULT

-

$8.61

$8.61Spin-On Lube Filter B228

BaldwinDescription The Baldwin Oil Filter B228 is designed for maximum performance and durability. It has a weight of 0.4 lbs. The filter’s robust construction ensures that it can withstand harsh conditions. This oil filter is the perfect choice to keep dust, debris, and other contaminants out of your machine. Keep your worksite moving forward with this Baldwin Oil Filter. -

$104.69

$104.69Sany Aftermarket Strobe ML2 LED - 12-80V - Amb - Magnetic Mount - Ul - Abs Plastic Base - Class Iii - 1 Joule - 60 Single Fpm 361100M-A

AftermarketManufacturer : Aftermarket Part Name : Strobe ML2 LED - 12-80V - Amb - Magnetic Mount - Ul - Abs Plastic Base - Class Iii - 1 Joule - 60 Single Fpm Part Number/MPN : 361100M-A-LED

Keeping your Ditch Witch RT45 in peak operating condition starts with the right parts and a solid maintenance routine. Ensure your ride-on trencher stays in top shape with high-quality spin-on lube filters, strobes, and more. The RT45 is powered by a Deutz F3M2011 diesel engine delivering 42 hp and offers compatibility with multiple trenching, plowing, backhoe, and saw attachments. With a maximum trench depth of 63 in and industry-standard hydrostatic drive, this unit is purpose-built for installing buried utility lines. Don’t forget to stay on top of your maintenance—secure the parts you need to keep your Ditch Witch RT45 running smoothly!

Walk-Around Inspection

- Check engine oil, hydraulic fluid, coolant, and fuel levels

- Inspect tires or tracks, lug nuts, and wheel hubs for wear and torque

- Verify battery terminals are clean and the disconnect switch is in the correct position

- Inspect hoses, belts, lights, and decals for cracks, leaks, or fading

- Check trenching chain, backfill blade, boom, and auger for wear or damage

Daily Maintenance

- Check engine oil and coolant levels

- Inspect hydraulic hoses and filters for damage or leaks

- Clean air filter restriction indicator

- Grease tail roller, auger bearings, pivot points, and universal joints

- Check digging chain tension and sprocket alignment

Every 50 Hours

- Clean radiator and oil cooler fins with compressed air or spray wash

- Check belt tension on the alternator; adjust if needed

- Lubricate backfill blade swing and frame slide

Every 100 Hours

- Lubricate microtrencher tilt adjustment points

Every 500 Hours

- Change engine oil and replace oil filter

- Replace hydraulic return filter and primary fuel filter

- Inspect differential and gearbox oil levels

- Lubricate all cross bearings and universal joints

- Replace plow vibrator oil (if equipped)

Every 1,000 Hours

- Change differential and gearbox oil

- Drain and replace hydraulic oil and filter

As-Needed Maintenance

- Replace worn digging chains, teeth, sprockets, or plow blades

- Adjust or replace brake linkage, seat belt, and safety decals as needed

- Bleed air from hydraulic cylinders or level adjusters if operation becomes erratic

- Replace microtrencher spoils deflectors or clean vac hose passages

Final Maintenance Recommendations

Regular maintenance keeps your Ditch Witch RT45 operating safely and efficiently. For a full range of Ditch Witch parts, explore our extensive EquipmentShare parts catalog. If you can’t find the part you need, reach out to our parts experts for a custom order.

Popular Models

Sany SY215C Excavator Parts

Sany SY135C Compact Excavator Parts

Takeuchi TL8R2 Compact Track Loader Parts

Takeuchi TL12R2 Compact Track Loader Parts

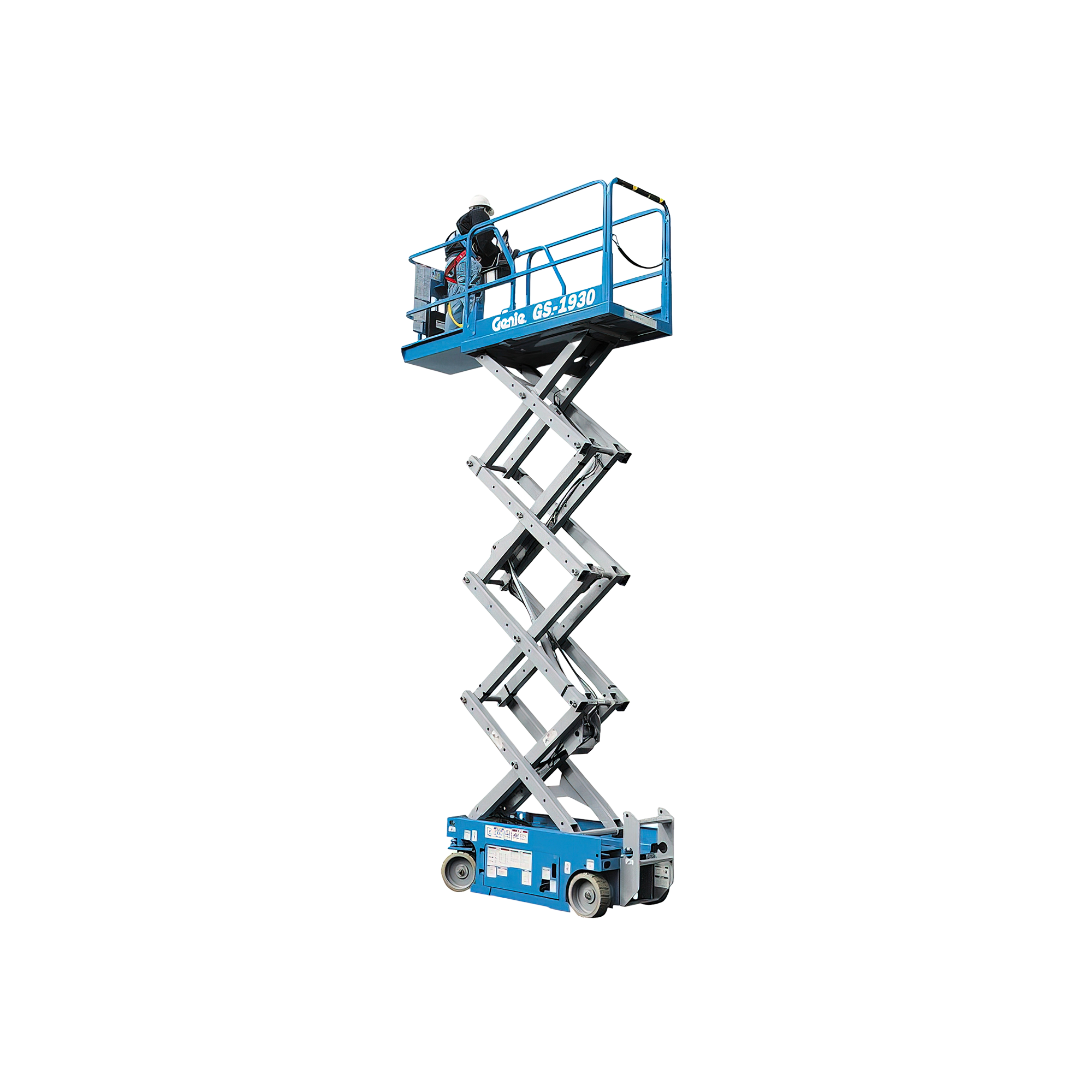

Genie GS-1930 Electric Scissor Lift Parts

Genie GS-2632 Electric Scissor Lift Parts

Skyjack SJIII 3219 Electric Scissor Lift Parts

MEC Micro 19 Electric Scissor Lift Parts

Genie GTH-5519 Telehandler Parts