Doosan C185WDO-T4F Air Compressor Parts

SEARCH Doosan C185WDO-T4F Air Compressor Parts

RESULT

-

Original price $78.09 - Original price $78.09Original price$78.09$78.09 - $78.09Current price $78.09| /

Wacker Neuson Jack-Swivel, 2000# 5100036814

Wacker NeusonOut of stockDescriptionThe Wacker Neuson Swivel Jack 5100036814 is the perfect solution for hauling materials and towing machines on your worksite. Its weight ...

View full detailsOriginal price $78.09 - Original price $78.09Original price$78.09$78.09 - $78.09Current price $78.09| /Sold out

Keeping your Doosan C185WDO-T4F in peak operating condition starts with the right parts and a solid maintenance routine. Ensure your air compressor stays in top shape with high-quality jack swivels and more. The C185WDO-T4F delivers 185 CFM at 100 psi in a towable, Tier 4 Final package, ideal for job sites needing reliable portable air. Don’t forget to stay on top of your maintenance—secure the parts you need to keep your Doosan C185 running smoothly!

Walk-Around Inspection

- Check for leaks or damage to hydraulic, air, and fuel lines

- Inspect radiator fins and cooler for debris or clogging

- Verify tires, lug nuts, and drawbar condition for safe towing

- Inspect safety decals and lights for legibility and operation

- Ensure guards, canopies, and doors are properly closed and latched

- Check for secure mounting of battery, jack, and fenders

Daily Maintenance

- Check engine oil, coolant, and compressor oil levels

- Inspect air filter condition indicators

- Drain water from fuel/water separator

- Inspect and clean radiator/cooler fins

- Verify fuel level and battery condition

- Grease jack stand and door hinges

Every 50 Hours

- Lubricate pivot points, drawbar, and axle bearings as needed

- Inspect compressor and engine air filters for clogging or dust buildup

- Check V-belts for wear and tension

- Inspect battery terminals for corrosion

Every 100 Hours

- Change engine oil and replace engine oil filter

- Clean engine air cleaner primary element

- Inspect radiator hoses and clamps

Every 250 Hours

- Inspect and tighten enclosure fasteners and mounting hardware

- Check engine and airend isolation mounts

- Clean radiator and compressor oil cooler thoroughly

Every 500 Hours

- Replace compressor oil filter element

- Replace fuel filters (pre-fuel and final fuel)

- Clean crankcase breather and separator housing

Every 1,000 Hours

- Replace compressor separator element

- Clean and inspect scavenge line and check valve

- Flush and refill compressor oil

Annual Maintenance

- Flush and replace engine coolant

- Inspect and clean the full cooling package and fan shroud

- Inspect frame, drawbar, wiring harness, and jack operation

- Touch up paint and apply corrosion protection where needed

As-Needed Maintenance

- Replace damaged or worn belts, hoses, fittings, and tires

- Clean or replace clogged air filters if pressure drop is excessive

- Replace batteries or terminals showing poor performance

- Service fuel system if diesel contamination or poor performance occurs

Final Maintenance Recommendations

Regular maintenance keeps your Doosan C185WDO-T4F operating safely and efficiently. For a full range of Doosan parts, explore our extensive EquipmentShare parts catalog. If you can’t find the part you need, reach out to our parts experts for a custom order.

Popular Models

Sany SY215C Excavator Parts

Sany SY135C Compact Excavator Parts

Takeuchi TL8R2 Compact Track Loader Parts

Takeuchi TL12R2 Compact Track Loader Parts

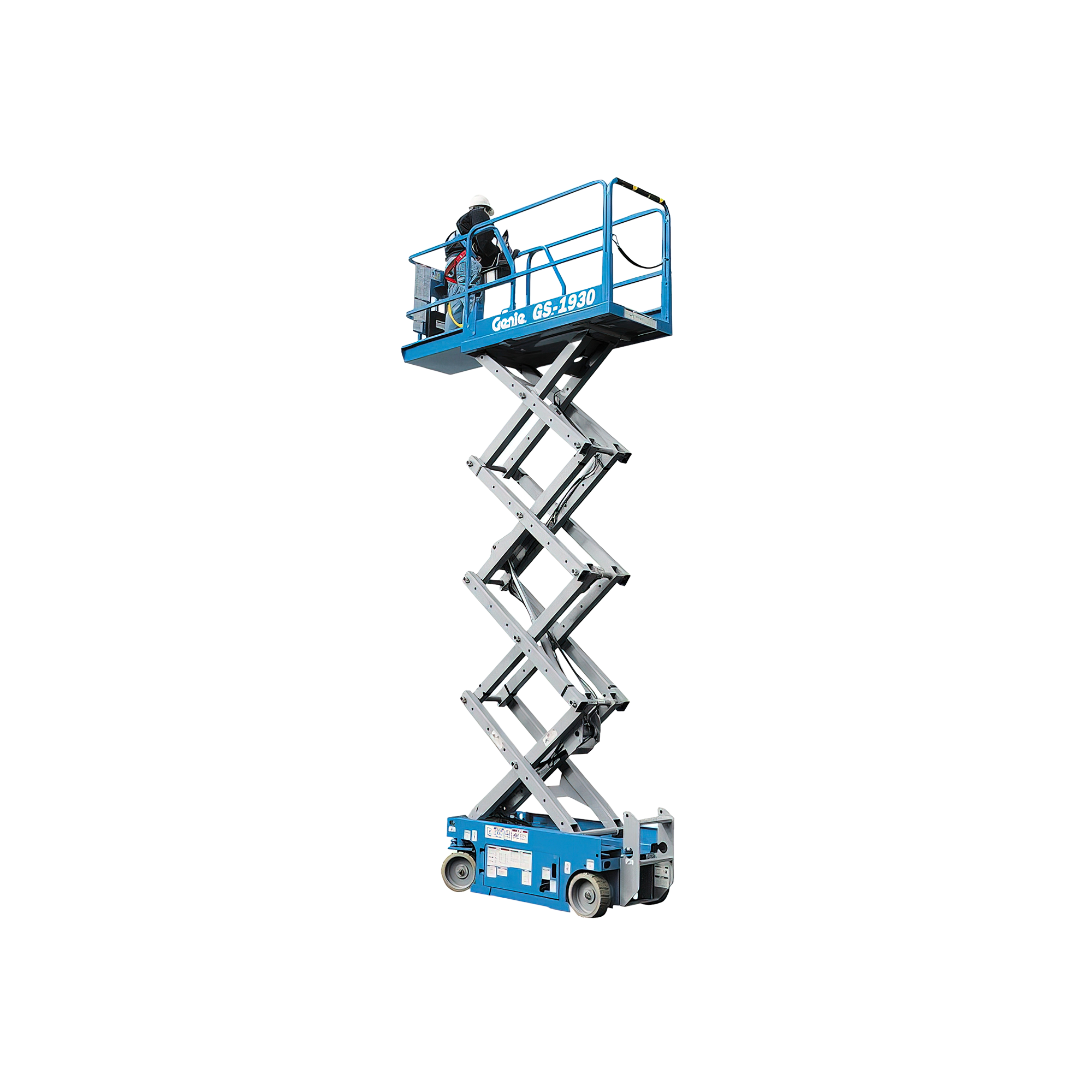

Genie GS-1930 Electric Scissor Lift Parts

Genie GS-2632 Electric Scissor Lift Parts

Skyjack SJIII 3219 Electric Scissor Lift Parts

MEC Micro 19 Electric Scissor Lift Parts

Genie GTH-5519 Telehandler Parts