Doosan G25P-7 Forklift Parts

SEARCH Doosan G25P-7 Forklift Parts

RESULT

-

$93.10

$93.10Wacker Neuson Fuel Filter Element 1000337856

Wacker NeusonDescription The Wacker Neuson Fuel Filter 1000337856 is essential for keeping your machine running at peak efficiency. Its weight is 1.1 lbs. The filter is designed to remove particles and contaminants from your fuel all while extending the life of your engine and increasing its performance. It is easy to install and requires minimal maintenance. With this filter, you can rest assured that your engine will be running smoothly and efficiently.

Keeping your Doosan G25P-7 in peak operating condition starts with the right parts and a solid maintenance routine. Ensure your forklift stays in top shape with high-quality fuel filter elements and more. Powered by a 2.4L Mitsubishi G424P(E) LPG engine, the G25P-7 delivers smooth and efficient performance for material handling in warehouses, construction, and outdoor applications. With a lift capacity of 2,500 kg (5,000 lbs) and reinforced safety systems including operator restraints, tilt lock, and automatic diagnostics, the G25P-7 is built for reliable productivity. Don’t forget to stay on top of your maintenance—secure the parts you need to keep your Doosan G25P-7 running smoothly!

Walk-Around Inspection

- Check for oil, coolant, fuel, or hydraulic leaks around the engine and mast

- Inspect tires for wear, damage, or foreign debris; verify proper inflation

- Test horn, lights, backup alarm, and seatbelt function

- Examine forks for cracks, bends, or worn tips; verify fork locking pin is engaged

- Inspect mast, chains, and rollers for wear or damage

- Check overhead guard and decals for visibility and integrity

Daily Maintenance

- Check engine oil, coolant, and LPG fuel level

- Inspect radiator and clean debris from fins

- Test brakes, steering, and all hydraulic functions

- Check operator restraint system, including seat adjustment and belt condition

- Inspect mast tilt, lift, and sideshift operations for smooth motion

Every 50–100 Hours

- Inspect belts, hoses, and wiring for wear or cracking

- Check battery terminals, electrolyte level, and clean as needed

- Lubricate mast pivot points and chain sheaves

- Drain water from fuel/water separator (if present)

Every 250 Hours

- Change engine oil and replace oil filter

- Replace fuel filter

- Inspect and clean air filter element

- Check transmission fluid level and condition

Every 500 Hours

- Replace air cleaner element (and safety element if needed)

- Inspect ignition system, spark plugs, and wires

- Check and clean radiator, confirm coolant protection level

- Inspect hydraulic lines and cylinders for wear and leaks

Every 1,000 Hours

- Replace transmission fluid and filter

- Replace hydraulic return filter

- Inspect rear axle and brake components

- Grease chassis and steering linkages

Every 2,000 Hours

- Flush and replace coolant with proper mix (as specified in manual)

- Check valve clearance and timing for G424P engine

- Inspect torque converter and shift performance (if ECT equipped)

As-Needed Maintenance

- Replace worn forks, seatbelt, decals, or tires

- Diagnose and resolve any MIL (malfunction indicator light) faults using onboard diagnostics

- Check and adjust inching pedal for proper modulation

- Inspect and reset electronic throttle or governor settings if driveability changes

Final Maintenance Recommendations

Regular maintenance keeps your Doosan G25P-7 operating safely and efficiently. For a full range of Doosan parts, explore our extensive EquipmentShare parts catalog. If you can’t find the part you need, reach out to our parts experts for a custom order.

Popular Models

Sany SY215C Excavator Parts

Sany SY135C Compact Excavator Parts

Takeuchi TL8R2 Compact Track Loader Parts

Takeuchi TL12R2 Compact Track Loader Parts

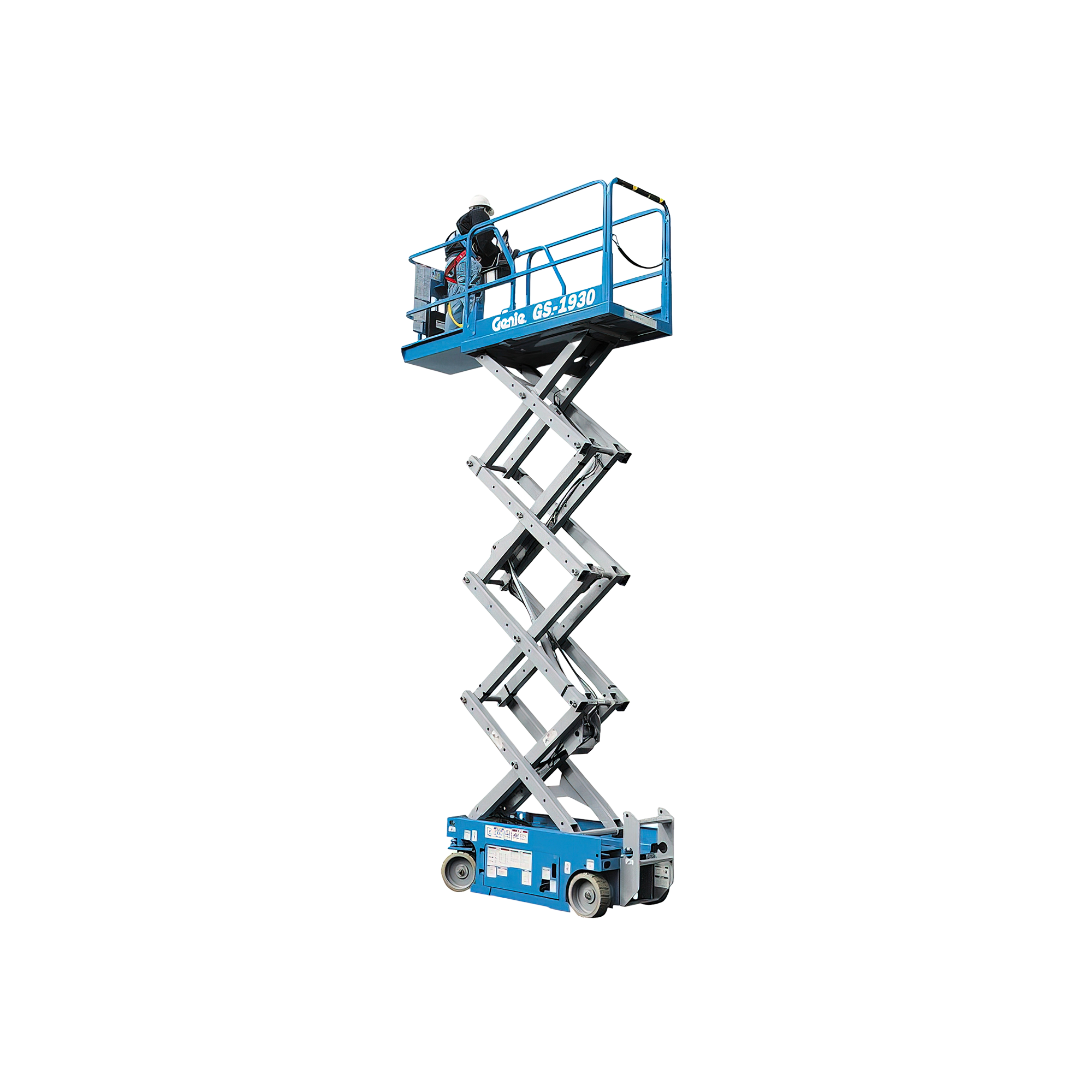

Genie GS-1930 Electric Scissor Lift Parts

Genie GS-2632 Electric Scissor Lift Parts

Skyjack SJIII 3219 Electric Scissor Lift Parts

MEC Micro 19 Electric Scissor Lift Parts

Genie GTH-5519 Telehandler Parts