JLG 1055 Telehandler Parts

SEARCH JLG 1055 Telehandler Parts

RESULT

-

$18.42

$18.42Spin-On Lube Filter BT7237

BaldwinDescription The Baldwin Oil Filter BT7237 is designed for maximum performance and durability. It has a weight of 1.2 lbs. The filter’s robust construction ensures that it can withstand harsh conditions. This oil filter is the perfect choice to keep dust, debris, and other contaminants out of your machine. Keep your worksite moving forward with this Baldwin Oil Filter.

Keeping your JLG 1055 in peak operating condition starts with the right parts and a solid maintenance routine. Ensure your rough terrain forklift stays in top shape with high-quality spin-on lube filters and more. The JLG 1055 is designed for maximum efficiency and stability, making it ideal for construction, lifting, and material handling tasks. Don’t forget to stay on top of your maintenance—secure the parts you need to keep your JLG 1055 running smoothly! Keep reading for a comprehensive maintenance guide for your machine.

Walk-Around Inspection

Before operating your JLG 1055, it’s crucial to perform a thorough walk-around inspection to prevent costly downtime and ensure operator safety. Regular inspections help identify issues early, allowing your rough terrain forklift to operate efficiently. Key areas to focus on during your inspection include:

- Checking for hydraulic leaks, loose hoses, or damaged connections.

- Inspecting tires for proper inflation and wear.

- Ensuring safety decals are in place and legible.

- Verifying that the platform and forks are secure.

Daily Inspection

- Check battery charge and connections.

- Inspect the hydraulic fluid level and condition.

- Test emergency stop function and horn operation.

- Ensure platform controls are responding correctly.

50-Hour Maintenance

- Change the hydraulic tank return filter.

- Inspect and lubricate swing bearings.

- Check all fasteners and tighten as needed.

250-Hour Maintenance

- Inspect and clean the hydraulic tank breather filter.

- Check and lubricate platform extension components.

- Inspect all electrical connections for corrosion.

500-Hour Maintenance

- Change engine oil and filter.

- Inspect and clean the battery terminals.

- Test and calibrate limit switches.

1,000-Hour Maintenance

- Flush and replace hydraulic oil.

- Inspect and service lift cylinders.

- Check for structural wear on the platform.

2,000-Hour Maintenance

- Replace wear pads and slide blocks.

- Inspect and replace any deteriorated hydraulic hoses.

Final Maintenance Recommendations

Regular maintenance keeps your JLG 1055 operating reliably. For a full range of JLG parts, explore our extensive EquipmentShare parts catalog. If you can't find the part you need, reach out to our parts experts for a custom order.

Popular Models

Sany SY215C Excavator Parts

Sany SY135C Compact Excavator Parts

Takeuchi TL8R2 Compact Track Loader Parts

Takeuchi TL12R2 Compact Track Loader Parts

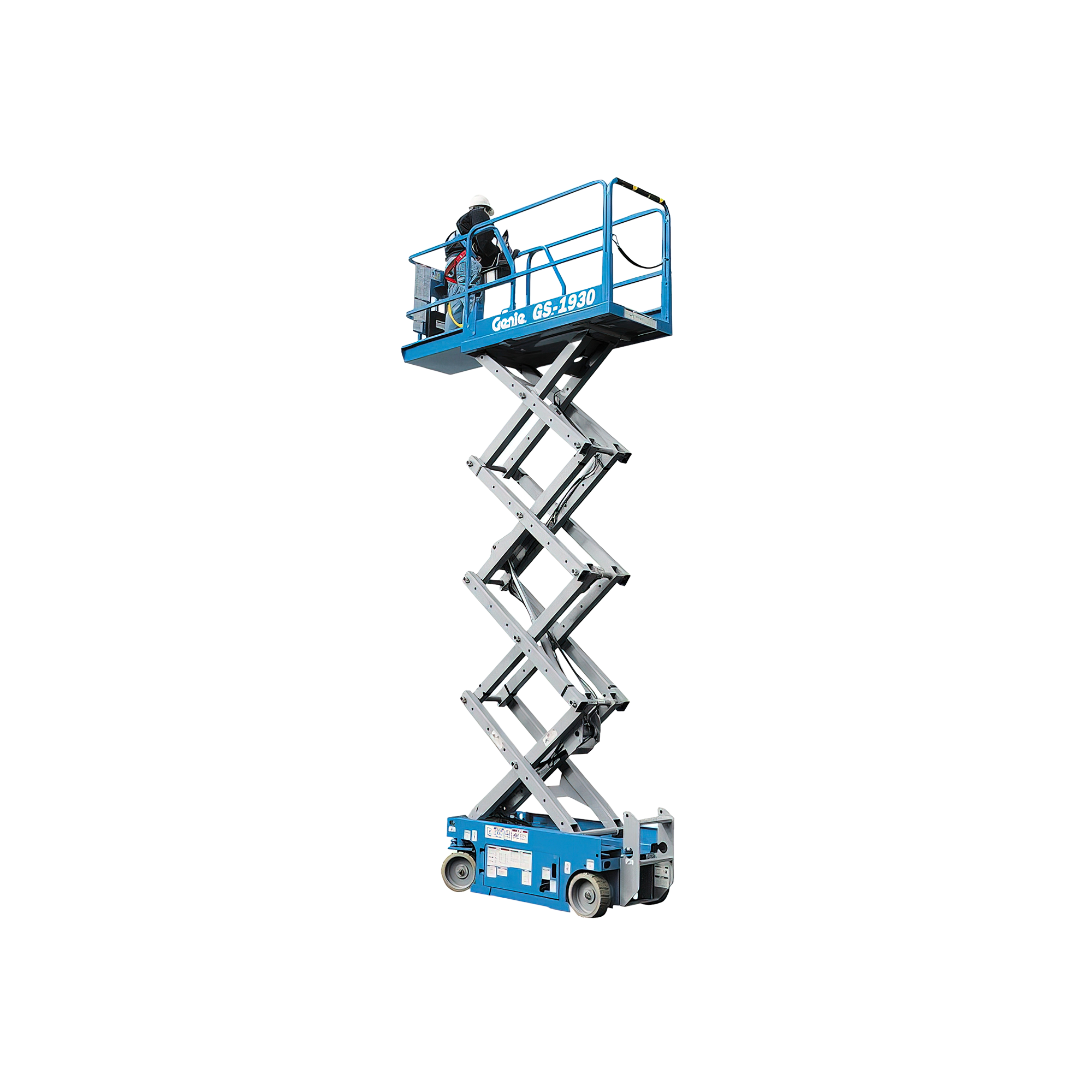

Genie GS-1930 Electric Scissor Lift Parts

Genie GS-2632 Electric Scissor Lift Parts

Skyjack SJIII 3219 Electric Scissor Lift Parts

MEC Micro 19 Electric Scissor Lift Parts

Genie GTH-5519 Telehandler Parts