JLG 400S Telescopic Boom Lift Parts

SEARCH JLG 400S Telescopic Boom Lift Parts

RESULT

-

Original price $0.72 - Original price $0.72Original price$0.72$0.72 - $0.72Current price $0.72| /

JLG Decal, (Drive Steer) 1702565

JLGIn stockDescriptionThe JLG Decal 1702565 is a must have label for your machine. Providing insights into the dangers of your machine is crucial to avoid any...

View full detailsOriginal price $0.72 - Original price $0.72Original price$0.72$0.72 - $0.72Current price $0.72| / -

Original price $41.20 - Original price $41.20Original price$41.20$41.20 - $41.20Current price $41.20| /

JLG Gauge, Fluid Level-Jlg Logo 7024441

JLGLow stockDescriptionThe JLG Gauge 7024441 is designed from quality materials for a long-lasting and dependable performance. Its weight is 0.2 lbs. This JLG ...

View full detailsOriginal price $41.20 - Original price $41.20Original price$41.20$41.20 - $41.20Current price $41.20| / -

Original price $1.78 - Original price $1.78Original price$1.78$1.78 - $1.78Current price $1.78| /

JLG O-Ring 3 1/4 X 3 7/16 X 3/32 3790152

JLGLow stockDescription The JLG O-Ring 3790152 is the perfect choice for your worksite. It has a weight of 0.0 lbs. It is made of high quality rubber for great...

View full detailsOriginal price $1.78 - Original price $1.78Original price$1.78$1.78 - $1.78Current price $1.78| / -

Original price $0.08 - Original price $0.08Original price$0.08$0.08 - $0.08Current price $0.08| /

JLG Washer Flat 10mm 10.5mm 21 2 4812000

JLGIn stockDescriptionThe JLG Washer 4812000 is designed to provide a secure and reliable connection, preventing the components on your machine from being loo...

View full detailsOriginal price $0.08 - Original price $0.08Original price$0.08$0.08 - $0.08Current price $0.08| / -

Original price $11.72 - Original price $11.72Original price$11.72$11.72 - $11.72Current price $11.72| /

JLG Sky Power Decal 1705460

JLGIn stockDescriptionThe JLG Decal 1705460 is a must have label for your machine. Providing insights into the dangers of your machine is crucial to avoid any...

View full detailsOriginal price $11.72 - Original price $11.72Original price$11.72$11.72 - $11.72Current price $11.72| / -

Original price $1.06 - Original price $1.06Original price$1.06$1.06 - $1.06Current price $1.06| /

JLG Washer .38 .406 .813 .138 4891600

JLGIn stockDescriptionThe JLG Washer 4891600 is designed to provide a secure and reliable connection, preventing the components on your machine from being loo...

View full detailsOriginal price $1.06 - Original price $1.06Original price$1.06$1.06 - $1.06Current price $1.06| / -

Original price $30.15 - Original price $30.15Original price$30.15$30.15 - $30.15Current price $30.15| /

JLG Skyline Magnet Mount 1001238472

JLGIn stockManufacturer: JLG Part Name: Skyline Magnet Mount Part Number/MPN: 1001238472

Original price $30.15 - Original price $30.15Original price$30.15$30.15 - $30.15Current price $30.15| / -

Original price $14.90 - Original price $14.90Original price$14.90$14.90 - $14.90Current price $14.90| /

MEC Cover, Outlet Box Weatherproof 91598

MECMore on the way!DescriptionThe MEC Cover 91598 is built to protect your equipment from the harsh elements your worksite may face. Its weight is 0.4 lbs. The durabi...

View full detailsOriginal price $14.90 - Original price $14.90Original price$14.90$14.90 - $14.90Current price $14.90| /Sold out -

Original price $4.65 - Original price $4.65Original price$4.65$4.65 - $4.65Current price $4.65| /

JLG 5" x 14.41" JLG Logo Decal 1702773

JLGIn stockDescriptionThe JLG Decal 1702773 is a must have label for your machine. Providing insights into the dangers of your machine is crucial to avoid any...

View full detailsOriginal price $4.65 - Original price $4.65Original price$4.65$4.65 - $4.65Current price $4.65| / -

Original price $0.42 - Original price $0.42Original price$0.42$0.42 - $0.42Current price $0.42| /

JLG Hex Head Screw Cap 8 .375-16 X 1.000 0681608

JLGIn stockDescriptionThe JLG Screw 0681608 is a perfect fit to secure your machine. It’s built with sturdy materials making it incredibly durable and long-la...

View full detailsOriginal price $0.42 - Original price $0.42Original price$0.42$0.42 - $0.42Current price $0.42| / -

Original price $1.12 - Original price $1.12Original price$1.12$1.12 - $1.12Current price $1.12| /

JLG Hydraulic Oil Decal 1701504

JLGOut of stockDescriptionThe JLG Decal 1701504 is a must have label for your machine. Providing insights into the dangers of your machine is crucial to avoid any...

View full detailsOriginal price $1.12 - Original price $1.12Original price$1.12$1.12 - $1.12Current price $1.12| /Sold out -

Original price $1.52 - Original price $1.52Original price$1.52$1.52 - $1.52Current price $1.52| /

JLG DSL Decal 1701505

JLGIn stockDescriptionThe JLG Decal 1701505 is a must have label for your machine. Providing insights into the dangers of your machine is crucial to avoid any...

View full detailsOriginal price $1.52 - Original price $1.52Original price$1.52$1.52 - $1.52Current price $1.52| / -

Original price $0.54 - Original price $0.54Original price$0.54$0.54 - $0.54Current price $0.54| /

JLG Lanyard Attach Decal 1704277

JLGOut of stockDescriptionThe JLG Decal 1704277 is a must have label for your machine. Providing insights into the dangers of your machine is crucial to avoid any...

View full detailsOriginal price $0.54 - Original price $0.54Original price$0.54$0.54 - $0.54Current price $0.54| /Sold out -

Original price $291.22 - Original price $291.22Original price$291.22$291.22 - $291.22Current price $291.22| /

JLG Deutz Engine Pulley 3580320

JLGLow stockDescriptionThe JLG Pulley 3580320 is designed to endure the harsh applications a worksite requires. Its weight is 3 lbs. It is built with robust ma...

View full detailsOriginal price $291.22 - Original price $291.22Original price$291.22$291.22 - $291.22Current price $291.22| /

Keeping your JLG 400S in peak operating condition starts with the right parts and a solid maintenance routine. Ensure your boom lift stays in top shape with high-quality hydraulic filter kits, decals, toggle switches, and more. The JLG 400S is designed for stability and versatility, making it ideal for outdoor jobs requiring high reach and maneuverability. Don’t forget to stay on top of your maintenance—secure the parts you need to keep your JLG 400S running smoothly! Keep reading for a comprehensive maintenance guide for your machine.

Walk-Around Inspection

Before operating your JLG 400S, it’s crucial to perform a thorough walk-around inspection to prevent costly downtime and ensure operator safety. Regular inspections help identify issues early, allowing your boom lift to operate efficiently. Key areas to focus on during your inspection include:

- Checking for hydraulic leaks, loose hoses, or damaged connections.

- Inspecting tires for proper inflation and wear.

- Ensuring safety decals are in place and legible.

- Verifying the platform and guardrails are secure.

Daily Inspection

- Check battery charge and connections.

- Inspect the hydraulic fluid level and condition.

- Test emergency stop function and horn operation.

- Ensure platform controls are responding correctly.

50-Hour Maintenance

- Change the hydraulic tank return filter.

- Inspect and lubricate swing bearings.

- Check all fasteners and tighten as needed.

250-Hour Maintenance

- Inspect and clean the hydraulic tank breather filter.

- Check and lubricate platform extension components.

- Inspect all electrical connections for corrosion.

500-Hour Maintenance

- Change engine oil and filter.

- Inspect and clean the battery terminals.

- Test and calibrate limit switches.

1,000-Hour Maintenance

- Flush and replace hydraulic oil.

- Inspect and service lift cylinders.

- Check for structural wear on the platform.

2,000-Hour Maintenance

- Replace wear pads and slide blocks.

- Inspect and replace any deteriorated hydraulic hoses.

Final Maintenance Recommendations

Regular maintenance keeps your JLG 400S operating reliably. For a full range of JLG parts, explore our extensive EquipmentShare parts catalog. If you can't find the part you need, reach out to our parts experts for a custom order.

Popular Models

Sany SY215C Excavator Parts

Sany SY135C Compact Excavator Parts

Takeuchi TL8R2 Compact Track Loader Parts

Takeuchi TL12R2 Compact Track Loader Parts

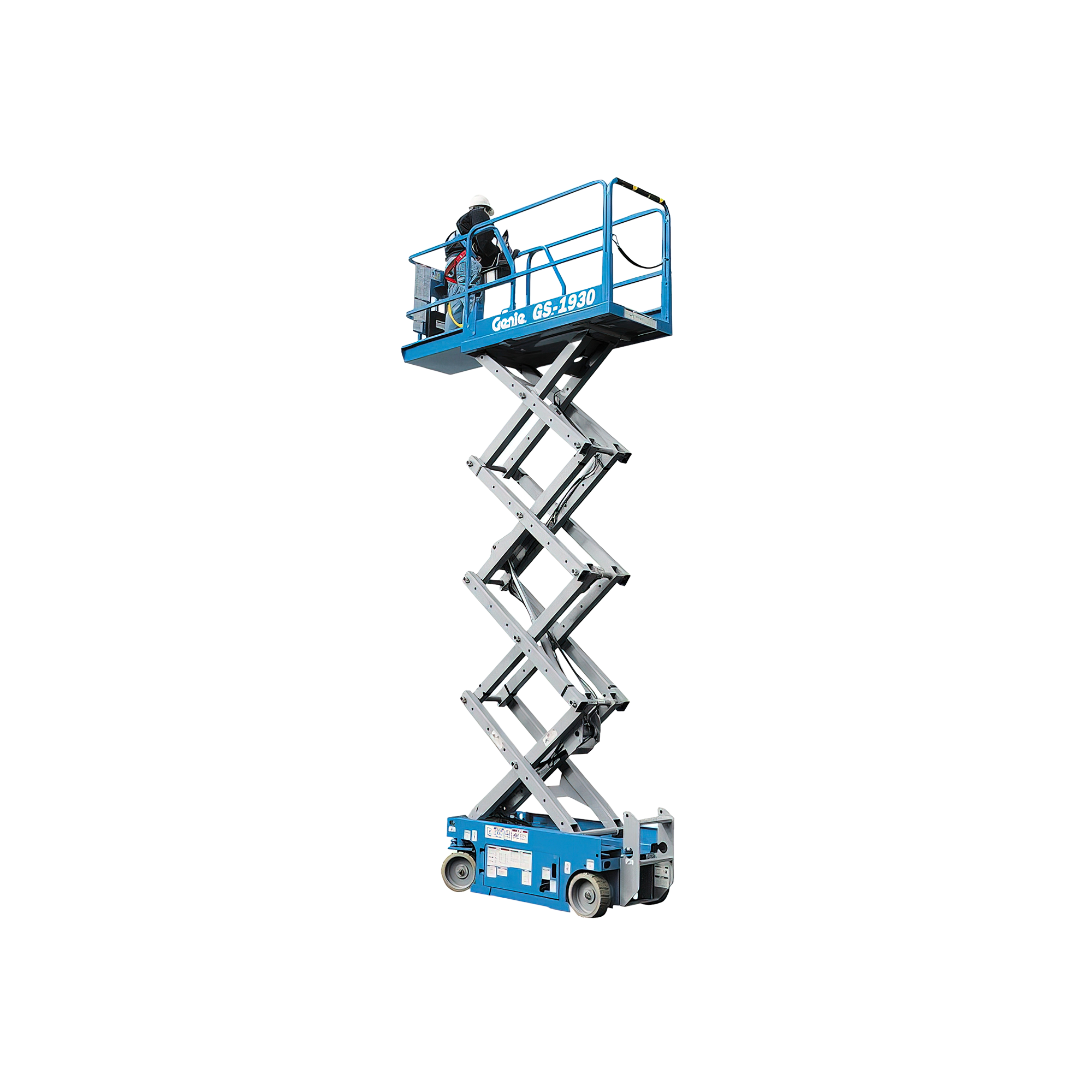

Genie GS-1930 Electric Scissor Lift Parts

Genie GS-2632 Electric Scissor Lift Parts

Skyjack SJIII 3219 Electric Scissor Lift Parts

MEC Micro 19 Electric Scissor Lift Parts

Genie GTH-5519 Telehandler Parts