Sany STH1256A Telehandler Parts

SEARCH Sany STH1256A Telehandler Parts

RESULT

-

Original price $67.57 - Original price $67.57Original price$67.57$67.57 - $67.57Current price $67.57| /

Sany Fuel Water Separator FS1098 GLQ008495953

SanyIn stockDescription The Sany Water Filter GLQ008495953 is the perfect solution to filter out contaminants from the water inside your machine. Its weight is...

View full detailsOriginal price $67.57 - Original price $67.57Original price$67.57$67.57 - $67.57Current price $67.57| / -

Original price $94.60 - Original price $94.60Original price$94.60$94.60 - $94.60Current price $94.60| /

Sany Fuel Filter Element 160604020027A

SanyLow stockDescriptionThe Sany Fuel Filter 160604020027A is essential for keeping your machine running at peak efficiency. Its weight is 0.57 lbs. The filter ...

View full detailsOriginal price $94.60 - Original price $94.60Original price$94.60$94.60 - $94.60Current price $94.60| / -

Original price $101.34 - Original price $101.34Original price$101.34$101.34 - $101.34Current price $101.34| /

Sany Main Cartridge Of Air Cleaner B222100000060

SanyIn stockDescriptionThe Sany Air Filter B222100000060 prevents dust and other harmful particles from entering your engine which can create a number of probl...

View full detailsOriginal price $101.34 - Original price $101.34Original price$101.34$101.34 - $101.34Current price $101.34| / -

Original price $51.66 - Original price $51.66Original price$51.66$51.66 - $51.66Current price $51.66| /

Sany Air Filter Core B222100000026

SanyIn stockDescription The Sany Air Filter B222100000026 prevents dust and other harmful particles from entering your engine which can create a number of prob...

View full detailsOriginal price $51.66 - Original price $51.66Original price$51.66$51.66 - $51.66Current price $51.66| / -

Original price $21.25 - Original price $21.25Original price$21.25$21.25 - $21.25Current price $21.25| /

Sany Engine Oil Filter Core 60004624

SanyOut of stockDescriptionThe Sany Oil Filter 60004624 is designed for maximum performance and durability. It has a weight of 1.8 lbs. The filter’s robust constru...

View full detailsOriginal price $21.25 - Original price $21.25Original price$21.25$21.25 - $21.25Current price $21.25| /Sold out

Searching for parts to keep your SANY STH1256A performing at its peak? Ensure your telehandler stays in top condition with a fuel water separator, an air filter core, an oil filter core, and more. The SANY STH1256A is designed for heavy-duty lifting applications and is powered by a robust engine, providing exceptional reliability and efficiency. With its durable construction and advanced controls, the STH1256A is built to handle demanding jobs with ease. Don’t forget to stay on top of your maintenance—secure the parts you need to keep your STH1256A running smoothly! Keep reading for a comprehensive maintenance guide for your machine.

Walk-Around Inspection

Before operating your SANY STH1256A, it’s crucial to perform a thorough walk-around inspection to prevent costly downtime and ensure operator safety. Regular inspections help identify issues early, allowing your telehandler to continue operating efficiently. Below are key areas to focus on during your inspection:

- Check for any signs of coolant and oil leaks around the machine.

- Inspect the engine compartment for any loose belts, debris, or damaged components.

- Examine the hydraulic hoses and connectors for leaks or visible wear.

- Ensure the tires and wheel rims are in good condition, with proper inflation and no visible damage.

- Check the boom, attachment points, and structural components for cracks or excessive wear.

- Verify that all safety decals and labels are in place and legible.

- Test all lights, indicators, and safety equipment inside the cab.

Daily Inspection

To maximize the life of your SANY STH1256A and avoid unexpected issues, a daily inspection should be part of your routine. Follow these steps:

- Check the engine coolant level and refill if necessary.

- Verify the engine oil level using the dipstick and add oil if required.

- Inspect the air filter and remove any accumulated dust or debris.

- Check the hydraulic oil level and ensure there are no visible leaks.

- Drain water from the fuel and water separator to maintain fuel quality.

- Inspect the battery terminals for corrosion and secure connections.

- Confirm proper brake function and check the transmission fluid level.

- Lubricate all grease points, removing excess grease to prevent buildup.

50-Hour Maintenance

At every 50-hour interval, routine maintenance helps catch early signs of wear and tear. Perform the following tasks:

- Lubricate the driveshaft and outriggers to ensure smooth movement.

- Inspect the steering axle and drive axle for leaks and damage.

- Clean the drive axle and steering axle breathers.

- Check the differential, main reducer, and planetary hub oil levels.

- Verify the boom wear pads for any signs of deterioration.

- Inspect and tighten all key fasteners, including axle hub fasteners.

250-Hour Maintenance

Every 250 hours, more in-depth maintenance checks are required. These tasks help ensure your telehandler remains in peak condition:

- Change the engine oil and replace the oil filter to maintain engine health.

- Inspect and clean the cooling system, including the radiator and hydraulic oil cooler.

- Lubricate the hydraulic cylinder pivot points for optimal performance.

- Check and adjust the serpentine belt tension, replacing it if necessary.

- Clean and inspect the battery terminals and cables.

- Check the fuel filter and replace it if needed to prevent fuel contamination.

500-Hour Maintenance

At 500-hour intervals, additional maintenance tasks are necessary to keep the machine running efficiently:

- Replace the hydraulic oil return filter to maintain system cleanliness.

- Inspect and adjust the transmission fluid level, changing the transmission oil if required.

- Clean or replace the diesel exhaust fluid (DEF) tank filter.

- Perform a full inspection of the boom structure and hydraulic hoses.

- Lubricate all major joints and moving components.

1000-Hour Maintenance

Comprehensive checks and part replacements at 1000-hour intervals prevent long-term wear issues. Key maintenance includes:

- Change the hydraulic oil and filter to ensure proper hydraulic system performance.

- Inspect and clean the fuel tank strainer to prevent contamination.

- Replace the pilot line filter and inspect the accumulator.

- Clean and inspect the engine exhaust system for leaks or blockages.

- Check and service the air conditioning system, including refrigerant levels.

Find the Right Parts for Your SANY STH1256A

For a larger selection of SANY products, check out our extensive SANY parts catalog. Still can't find the part you need? Reach out to one of our parts experts to place a custom order.

Popular Models

Sany SY215C Excavator Parts

Sany SY135C Compact Excavator Parts

Takeuchi TL8R2 Compact Track Loader Parts

Takeuchi TL12R2 Compact Track Loader Parts

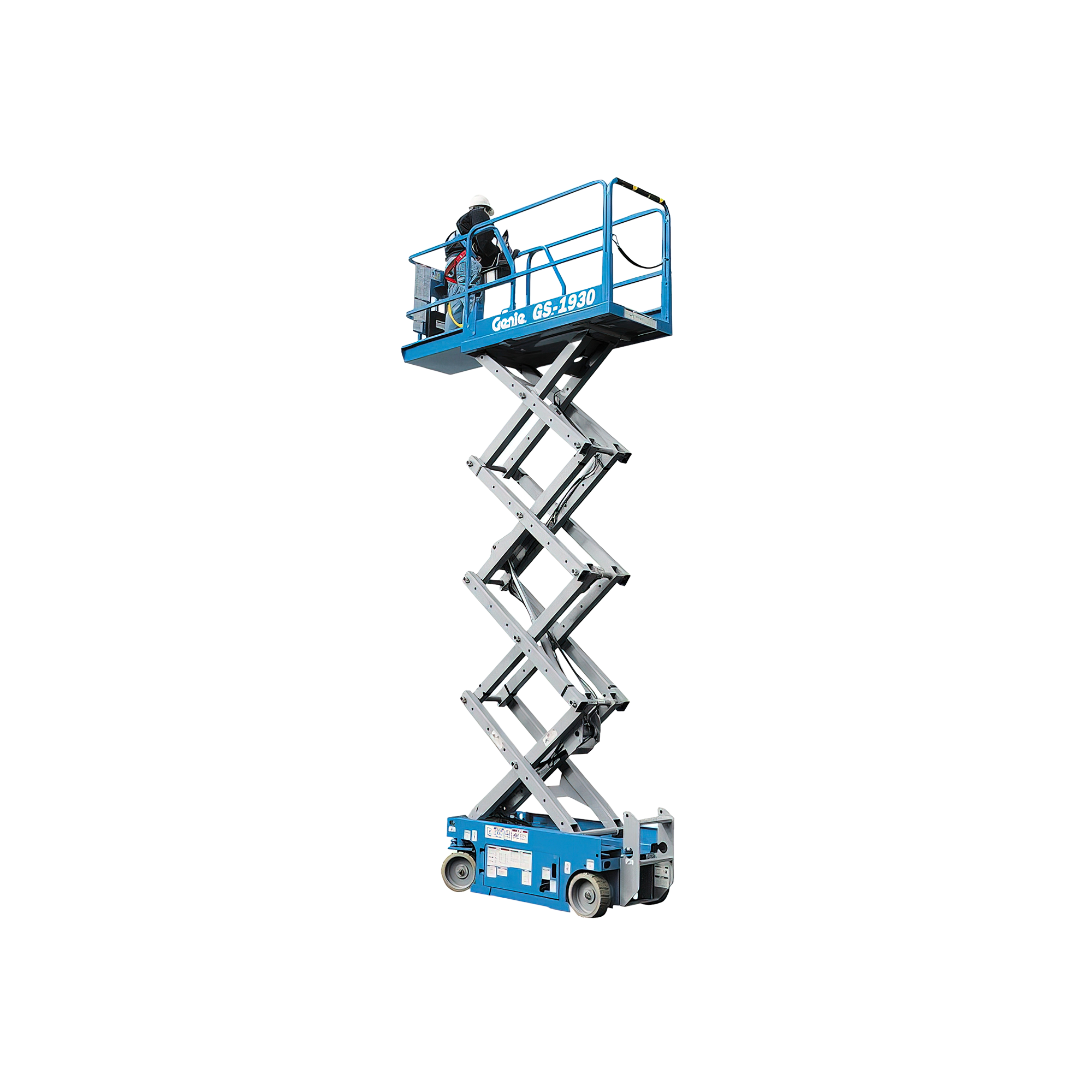

Genie GS-1930 Electric Scissor Lift Parts

Genie GS-2632 Electric Scissor Lift Parts

Skyjack SJIII 3219 Electric Scissor Lift Parts

MEC Micro 19 Electric Scissor Lift Parts

Genie GTH-5519 Telehandler Parts