Hydraulic systems are critical to the performance of modern construction equipment. Simply put, hydraulic systems convert fluid pressure into mechanical force, enabling machines to lift impressive loads and perform incredible feats of power.

Central to a hydraulic system’s design are hydraulic cylinders. In hydraulic cylinders, fluid pressure is converted to mechanical force by driving a piston, powering boom arms, buckets and attachments.

Depending on the design of your particular machine, it may feature between one and several hydraulic cylinders. These cylinders are strategically located at various points on the machine to perform specific functions.

In this guide, we’ll cover the basics of hydraulic cylinders and how they enable construction equipment to do its job.

What is a Hydraulic Cylinder?

In its most basic form, a hydraulic cylinder works by using pressurized fluid to push a piston, which in turn moves something heavy or does mechanical work. When hydraulic fluid is pumped into one end of the cylinder, it pushes the piston, and when fluid is released or pumped out, the piston returns.

This in/out movement of the cylinder’s piston is used to lift, push or perform other tasks, such as lifting a boom arm into the air or driving an auger into the ground. While all hydraulic cylinders are based on this simple design, there are several types of hydraulic cylinders you might find on your machine.

Types of Hydraulic Cylinders:

Single-acting Cylinders:

Single-acting cylinders have a simple design with a single hydraulic port for fluid input. They operate by applying hydraulic pressure to extend the cylinder’s piston. They are often seen in dump trucks for raising the bed, as well as in dozer blades for pushing material.

Double-acting Cylinders:

Double-acting cylinders have two hydraulic ports, allowing hydraulic fluid to enter and exit the cylinder, enabling controlled movement in both directions. Double-acting cylinders are extensively used in heavy construction equipment like excavators, where precise control of digging and lifting operations is essential.

Tie-rod Cylinders:

Tie-rod cylinders have a cylindrical shape with external tie rods that provide structural support. These rods hold the cylinder together and allow for easy maintenance and repair. Tie-rod cylinders are employed in heavy construction equipment likeloaders, backhoes and cranes. The tie-rod design makes these cylinders easy to disassemble and service.

Welded Body Cylinders:

Welded body cylinders have a one-piece, welded cylinder body that eliminates the need for tie rods. They are built to withstand high pressures and rugged conditions. Welded body cylinders are commonly used in hydraulic systems of excavators, where high strength and reliability are vital, especially in the digging and lifting functions.

Telescopic Cylinders:

Telescopic cylinders consist of multiple nested stages that extend and retract, providing a longer stroke length within a compact space. These cylinders are often seen in equipment such as cranes and dump trucks, where a longer reach or height is required without extending the overall length of the equipment.

Tandem Cylinders:

Tandem cylinders are essentially two or more cylinders mounted in parallel or series, working together to provide increased force or speed. By combining the power of multiple cylinders, tandem cylinders can deliver higher force or speed, making them suitable for heavy-duty applications where standard cylinders may fall short.

Since hydraulic cylinders need to be strong, durable and resistant, they are typically made from stainless steel. Stainless steel provides good resistance to internal forces that act on the cylinder barrel while also withstanding corrosion and harsh environments.

The size of your machine’s hydraulic cylinders typically varies according to the size of your machine, the load and force requirements of the particular cylinders, and the required stroke length. Smaller machines commonly feature shorter, more compact cylinders; while larger machines feature larger cylinders with longer stroke lengths.

Parts of a Hydraulic Cylinder

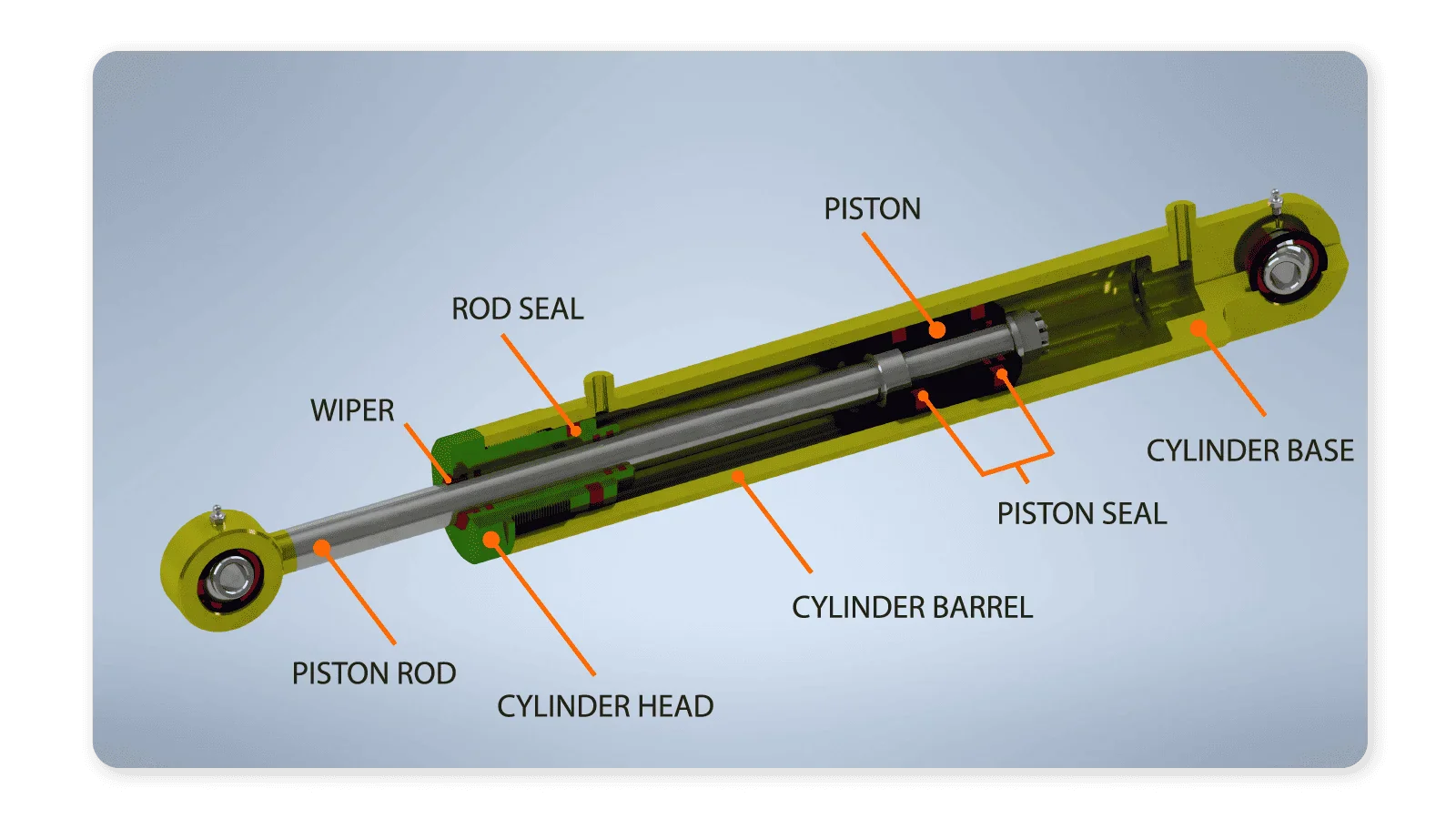

While the function of hydraulic cylinders is rather straightforward, they contain a number of intricate components that are required in order for them to function properly.

The main components of a hydraulic cylinder are:

Cylinder Barrel:

The cylinder barrel is the main cylindrical body of the hydraulic cylinder. It houses the piston, and hydraulic pressure acts on the inner surface to create movement.

Cylinder Head:

The cylinder head is one end of the cylinder barrel, and it contains ports for hydraulic fluid to enter and exit the cylinder. It helps seal the hydraulic pressure inside the cylinder.

Cylinder Base:

The cylinder base is the opposite end of the cylinder barrel from the cylinder head. It provides a surface for the cylinder to mount or connect to other machinery.

Rod Seal:

The rod seal is a critical sealing component that prevents hydraulic fluid from leaking out of the cylinder along the piston rod.

Wiper:

The wiper, also known as a rod wiper or dust seal, is a protective component that cleans the piston rod as it retracts into the cylinder, preventing dirt and contaminants from entering the cylinder.

Piston:

The piston is a movable component inside the cylinder barrel. It divides the cylinder into two chambers and is pushed or pulled by hydraulic pressure, performing mechanical work.

Piston Rod:

The piston rod is attached to the piston and extends out of the cylinder head. It connects to the load or the equipment that needs to be moved or controlled.

Piston Seal:

The piston seal ensures a tight seal between the piston and the cylinder barrel, preventing hydraulic fluid from leaking between the two chambers.

Washer:

Washers may be used to provide additional support or spacing within the cylinder assembly.

O-ring:

O-rings are sealing components used in various locations within the hydraulic cylinder to prevent fluid leaks and maintain hydraulic pressure.

The Importance of Seals in Hydraulic Cylinders

Seals are a key component in hydraulic cylinders. A hydraulic cylinder’s seals play an important role in preventing hydraulic fluid from leaking out and keeping external contaminants from entering the system.

Additionally, in double-acting hydraulic cylinders, seals help separate the fluid chambers on either side of the piston, allowing for differential pressure and enabling the piston to move in response to hydraulic force.

When hydraulic cylinder seals become faulty or compromised, a range of negative consequences can occur. The most immediate risks are fluid leakage, ingress of contaminants into the system and safety risks to operators.

Maintenance of Hydraulic Cylinders

Preventive maintenance is essential to preserving the quality of your machine’s hydraulic cylinders. Regular visual inspections should be conducted to check for signs of damage, leaks or wear.

In addition, hydraulic filters should be changed according to the intervals laid out in the machine’s service manual. Failing to change hydraulic fluid filters on time could lead to the degradation of the cylinders’ seals, causing damage to the hydraulic system.

Not only should you maintain your machine’s hydraulic cylinders according to a well-established maintenance plan, but you should also familiarize yourself with the signs of defective or malfunctioning cylinders. Some common signs to look out for include reduced performance, unusual noises and uneven wear on cylinder rods.

Final Thoughts

Hydraulic cylinders are critical to the performance of heavy equipment. While hydraulic cylinders come in many shapes, sizes and types, all cylinders require adequate maintenance in order to function smoothly.

The EquipmentShare Shop can help you maintain your construction equipment’s hydraulic cylinders. Our growing online catalog makes it easy to find seals, gaskets and other replacement parts to keep your machine’s cylinders operating as intended. If you need help locating a part, reach out to our dedicated parts experts and get personalized assistance.