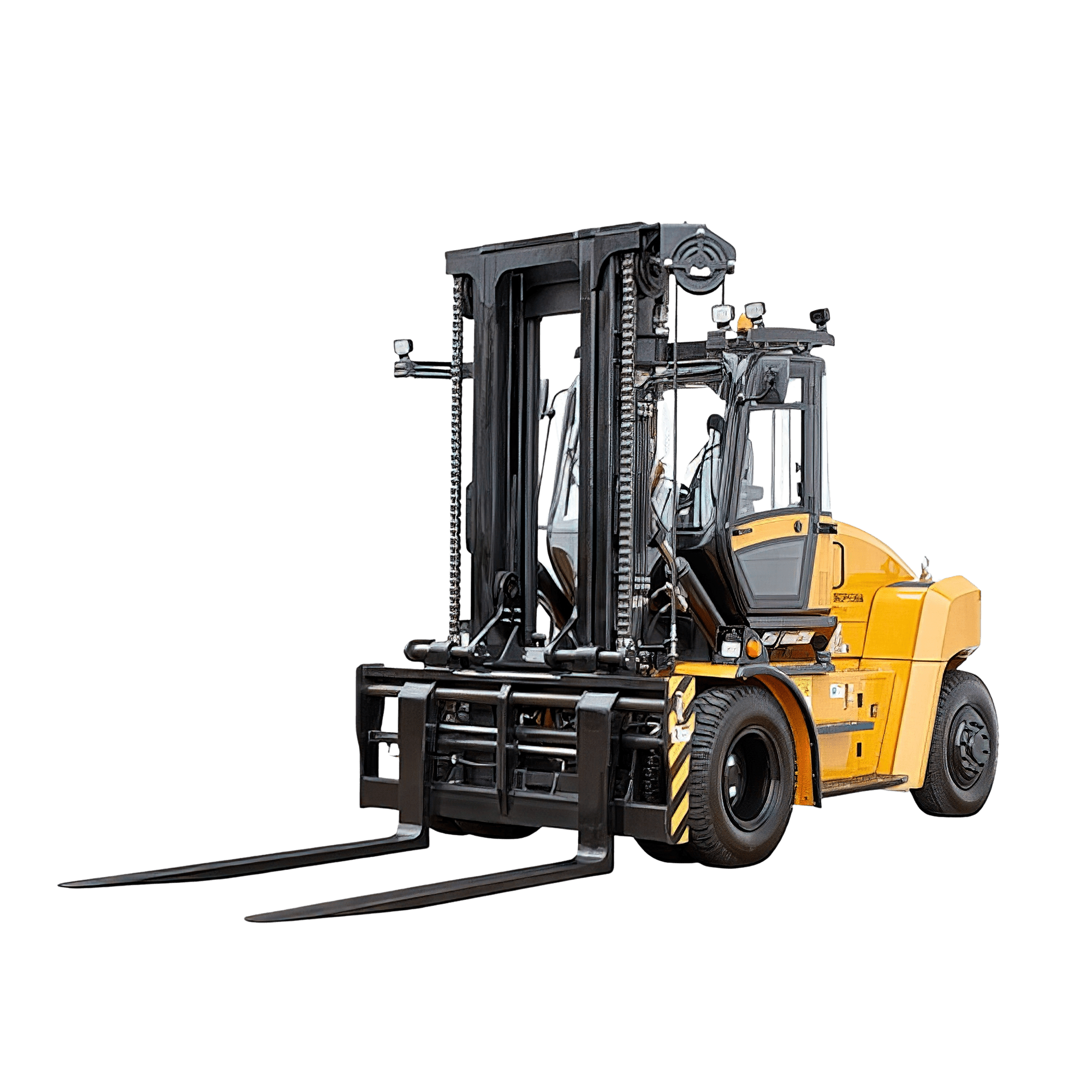

Clark C25CL Forklift Parts

SEARCH Clark C25CL Forklift Parts

Close

Refine By

RESULT

-

$38.29

$38.29Donaldson Safety Filter P534885

DonaldsonDescription The Donaldson Filter P534885 is designed to keep your machine running smoothly and efficiently. It has a weight of 0.7 lbs. It offers great protection against dust, debris, and other contaminants, ensuring a high level of performance. With a durable design and easy installation, this filter is a must-have for any construction job.

Can't find the part you're looking for?

Can't find the part you're looking for?

CALL US: 573-355-6493

EMAIL US: shop@equipmentshare.com

Can't find the part you're looking for?

Keeping your Clark C25CL in peak operating condition starts with the right parts and a solid maintenance routine. Ensure your lift truck stays in top shape with high-quality safety filters and more. The C25CL delivers strength and fuel efficiency for demanding warehouse and yard environments. Don’t forget to stay on top of your maintenance—secure the parts you need to keep your Clark C25CL running smoothly!

Walk-Around Inspection

- Inspect forks, upright, and carriage for cracks, bends, or wear

- Check hydraulic hoses, cylinders, and connectors for leaks

- Ensure mast chains and anchors are properly secured

- Look for loose or missing fasteners, latches, and pins

- Inspect seatbelt, steering, and operator platform for damage

- Ensure all decals, safety signs, and data plates are in place

- Verify tire condition, air pressure, and lug nut torque

Daily Maintenance

- Check engine oil and coolant levels before operation

- Inspect transmission fluid and hydraulic fluid levels

- Clean radiator, air filter, and cooling fins

- Drain moisture from fuel/water separator (diesel models)

- Test brakes, inching pedal, and parking brake function

- Check horn, lights, gauges, and warning alarms

- Examine seatbelt and operator controls for proper function

Every 50 Hours

- Lubricate steer axle, mast rollers, and tilt cylinder pivots

- Check battery terminals, water level, and state of charge

- Inspect LPG tank mount and hose condition (LPG models)

- Check fan belt tension and wear

Every 250 Hours

- Change engine oil and replace oil filter

- Clean fuel tank vent and fuel filler strainer

- Inspect radiator hoses and clamp integrity

- Check differential oil level and top off as needed

Every 500 Hours

- Replace engine air filter element

- Replace hydraulic return filter

- Inspect and clean transmission breather

- Check LPG regulator filter (if equipped)

Every 1,000 Hours

- Replace transmission oil and filter

- Replace spark plugs (gasoline models)

- Inspect and clean exhaust components and shields

- Flush cooling system and replace coolant

Every 2,000 Hours

- Change differential and final drive oil

- Check engine valve clearance and adjust if necessary

- Replace LPG tank mounting hardware if worn

- Replace PCV valve (gas models)

Annual Maintenance

- Inspect complete frame, overhead guard, and ROPS/FOPS welds

- Verify load rating data plate and safety decals are legible

- Inspect steering linkage, ball joints, and tilt cylinder ends

- Check alternator, starter, and wiring harness condition

As-Needed Maintenance

- Replace worn or damaged forks, chains, or mast rollers

- Replace any hydraulic hose showing bulges, cracks, or leaks

- Repair or replace defective lights, switches, or gauges

- Replace wheels, tires, or brake components if safety is compromised

Final Maintenance Recommendations

Regular maintenance keeps your Clark C25CL operating safely and efficiently. For a full range of Clark parts, explore our extensive EquipmentShare parts catalog. If you can’t find the part you need, reach out to our parts experts for a custom order.

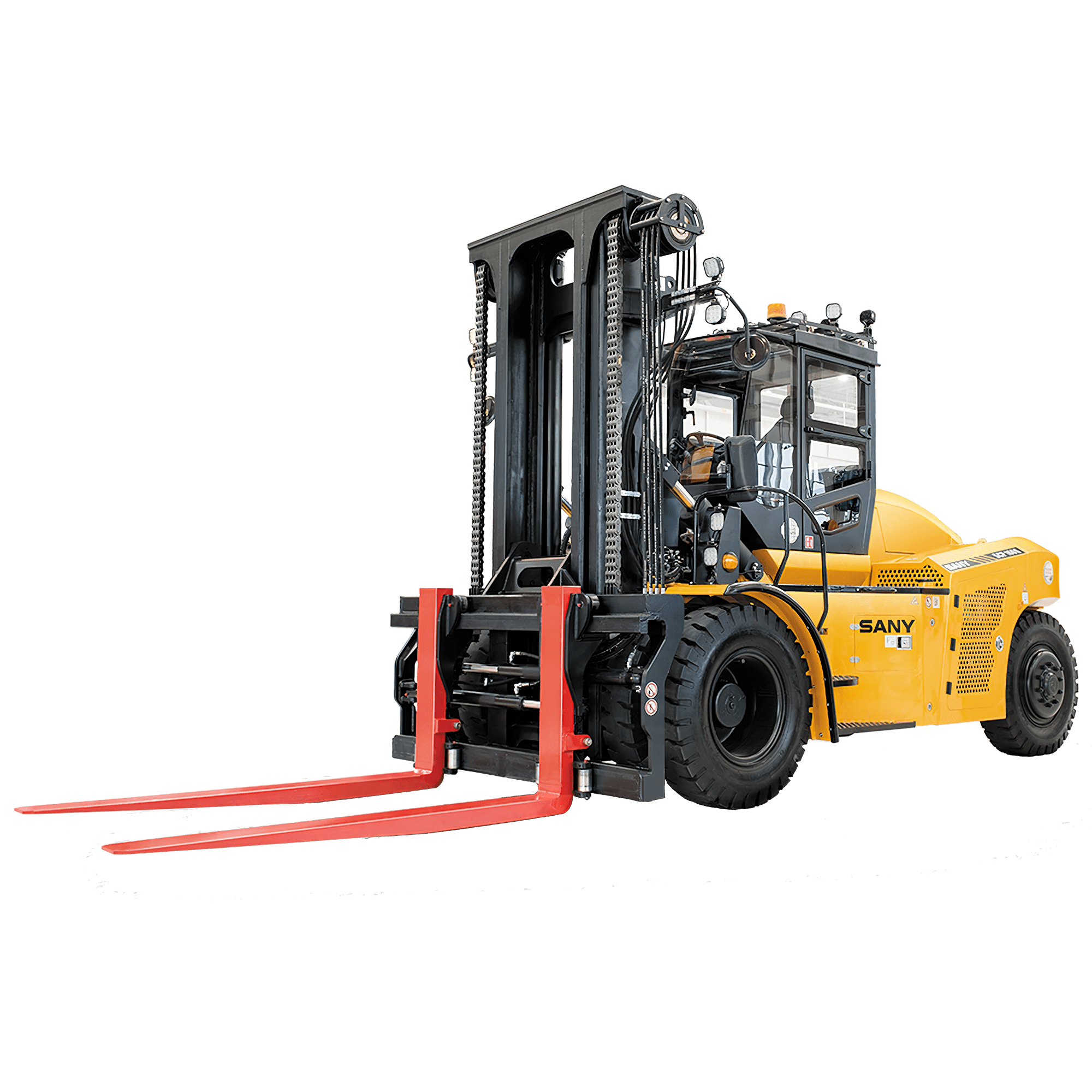

Popular Models

Sany SY215C Excavator Parts

Sany SY135C Compact Excavator Parts

Takeuchi TL8R2 Compact Track Loader Parts

Takeuchi TL12R2 Compact Track Loader Parts

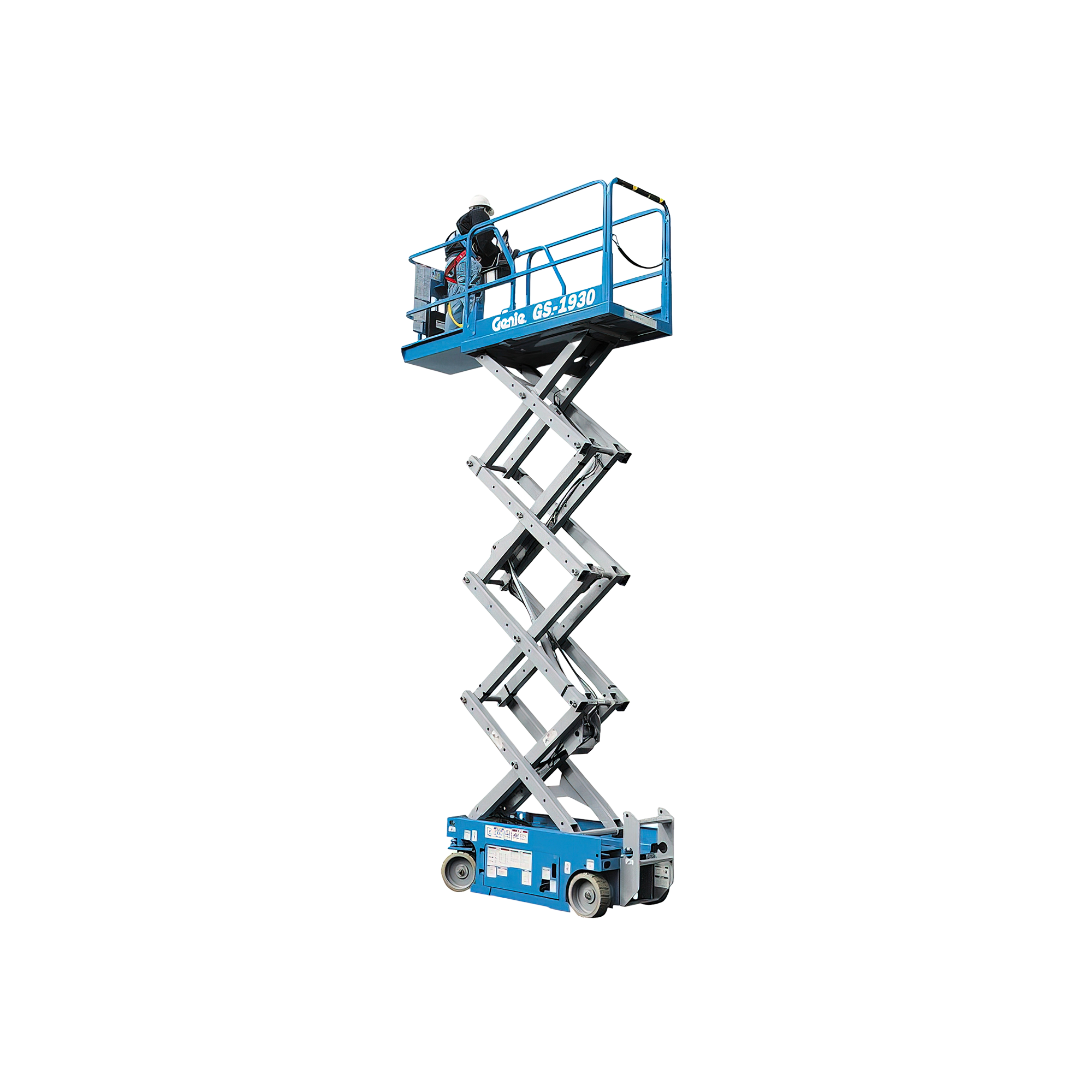

Genie GS-1930 Electric Scissor Lift Parts

Genie GS-2632 Electric Scissor Lift Parts

Skyjack SJIII 3219 Electric Scissor Lift Parts

MEC Micro 19 Electric Scissor Lift Parts

Genie GTH-5519 Telehandler Parts