JLG 600AJ Articulating Boom Lift Parts

SEARCH JLG 600AJ Articulating Boom Lift Parts

RESULT

-

Original price $1.68 - Original price $1.68Original price$1.68$1.68 - $1.68Current price $1.68| /

JLG Decal, Warning Crushing 1703804

JLGIn stockDescriptionThe JLG Decal 1703804 is a must have label for your machine. Providing insights into the dangers of your machine is crucial to avoid any...

View full detailsOriginal price $1.68 - Original price $1.68Original price$1.68$1.68 - $1.68Current price $1.68| / -

Original price $0.58 - Original price $0.58Original price$0.58$0.58 - $0.58Current price $0.58| /

JLG Decal, (Lift, Swing) 1702566

JLGIn stockDescriptionThe JLG Decal 1702566 is a must have label for your machine. Providing insights into the dangers of your machine is crucial to avoid any...

View full detailsOriginal price $0.58 - Original price $0.58Original price$0.58$0.58 - $0.58Current price $0.58| / -

Original price $60.68 - Original price $60.68Original price$60.68$60.68 - $60.68Current price $60.68| /

JLG Seal Kit 2901273

JLGLow stockDescriptionThe JLG Seal Kit 2901273 is perfect for protecting your machine and equipment against dirt, dust and other debris while keeping your wor...

View full detailsOriginal price $60.68 - Original price $60.68Original price$60.68$60.68 - $60.68Current price $60.68| / -

Original price $0.72 - Original price $0.72Original price$0.72$0.72 - $0.72Current price $0.72| /

JLG Decal, (Drive Steer) 1702565

JLGIn stockDescriptionThe JLG Decal 1702565 is a must have label for your machine. Providing insights into the dangers of your machine is crucial to avoid any...

View full detailsOriginal price $0.72 - Original price $0.72Original price$0.72$0.72 - $0.72Current price $0.72| / -

Original price $515.47 - Original price $515.47Original price$515.47$515.47 - $515.47Current price $515.47| /

JLG Bottom Tube Weld 4844817S

JLGLow stockManufacturer: JLG Part Name: Bottom Tube Weld Part Number/MPN: 4844817S

Original price $515.47 - Original price $515.47Original price$515.47$515.47 - $515.47Current price $515.47| / -

Original price $124.62 - Original price $124.62Original price$124.62$124.62 - $124.62Current price $124.62| /

JLG Potentiometer Switch 4360407

JLGIn stockDescriptionThe JLG Switch 4360407 is a must-have for your machine. Its weight is 0.4 lbs. It is constructed with robust materials to provide a long...

View full detailsOriginal price $124.62 - Original price $124.62Original price$124.62$124.62 - $124.62Current price $124.62| / -

Original price $46.76 - Original price $46.76Original price$46.76$46.76 - $46.76Current price $46.76| /

Genie Manual Box W-Decals 44743GT

GenieLow stockManufacturer: Genie Part Name: Manual Box W-Decals Part Number/MPN: 44743GT

Original price $46.76 - Original price $46.76Original price$46.76$46.76 - $46.76Current price $46.76| / -

Original price $30.15 - Original price $30.15Original price$30.15$30.15 - $30.15Current price $30.15| /

JLG Skyline Magnet Mount 1001238472

JLGIn stockManufacturer: JLG Part Name: Skyline Magnet Mount Part Number/MPN: 1001238472

Original price $30.15 - Original price $30.15Original price$30.15$30.15 - $30.15Current price $30.15| / -

Original price $1.85 - Original price $1.85Original price$1.85$1.85 - $1.85Current price $1.85| /

JLG Horn Decal 1702676

JLGIn stockDescriptionThe JLG Decal 1702676 is a must have label for your machine. Providing insights into the dangers of your machine is crucial to avoid any...

View full detailsOriginal price $1.85 - Original price $1.85Original price$1.85$1.85 - $1.85Current price $1.85| / -

Original price $0.62 - Original price $0.62Original price$0.62$0.62 - $0.62Current price $0.62| /

JLG Socket, 16-20 Ga 4460465

JLGIn stockDescriptionThe JLG Socket 4460465 provides an ideal solution for connecting and disconnecting components on construction machines. Its weight is 0....

View full detailsOriginal price $0.62 - Original price $0.62Original price$0.62$0.62 - $0.62Current price $0.62| / -

Original price $4.62 - Original price $4.62Original price$4.62$4.62 - $4.62Current price $4.62| /

JLG Decal, Legend (Plf) 1001108493

JLGIn stockDescriptionThe JLG Decal 1001108493 is a must have label for your machine. Providing insights into the dangers of your machine is crucial to avoid ...

View full detailsOriginal price $4.62 - Original price $4.62Original price$4.62$4.62 - $4.62Current price $4.62| / -

Original price $4.14 - Original price $4.14Original price$4.14$4.14 - $4.14Current price $4.14| /

JLG Decal, Max Cap. 500Lbs/227Kg 1001121801

JLGIn stockDescriptionThe JLG Decal 1001121801 is a must have label for your machine. Providing insights into the dangers of your machine is crucial to avoid ...

View full detailsOriginal price $4.14 - Original price $4.14Original price$4.14$4.14 - $4.14Current price $4.14| / -

Original price $0.54 - Original price $0.54Original price$0.54$0.54 - $0.54Current price $0.54| /

JLG Lanyard Attach Decal 1704277

JLGOut of stockDescriptionThe JLG Decal 1704277 is a must have label for your machine. Providing insights into the dangers of your machine is crucial to avoid any...

View full detailsOriginal price $0.54 - Original price $0.54Original price$0.54$0.54 - $0.54Current price $0.54| /Sold out

Searching for parts to keep your JLG 600AJ performing at its peak? Ensure your boom lift stays in top condition with high-quality outer air filters, hydraulic filters, boom angle sensors, and more. The JLG 600AJ is powered by a reliable engine designed for efficiency and durability, making it ideal for demanding job sites. Don’t forget to stay on top of your maintenance—secure the parts you need to keep your JLG 600AJ running smoothly! Keep reading for a comprehensive maintenance guide for your machine.

Walk-Around Inspection

Before operating your JLG 600AJ, it’s crucial to perform a thorough walk-around inspection to prevent costly downtime and ensure operator safety. Regular inspections help identify issues early, allowing your boom lift to operate efficiently. This process enables you to detect any leaks, loose components, or potential hazards that could affect performance and longevity. Key areas to focus on during your inspection include:

- Checking for hydraulic leaks, loose hoses, or damaged connections.

- Inspecting tires for proper inflation and wear.

- Ensuring visibility by cleaning mirrors, windows, and checking for proper lighting operation.

- Verifying the structural integrity of the boom and platform.

Daily Inspection

- Check engine oil and coolant levels, topping off as needed.

- Inspect the air filter indicator to determine if cleaning or replacement is necessary.

- Drain water and sediment from the fuel separator.

- Check hydraulic oil levels and refill if necessary.

- Grease all lubrication points to prevent premature wear.

50-Hour Maintenance

- Inspect and adjust tire pressure.

- Lubricate all pivot points.

- Check for loose fasteners and tighten as necessary.

250-Hour Maintenance

- Inspect and adjust the fan belt.

- Clean the air cleaner.

- Clean radiator fins and oil cooler fins.

- Inspect hydraulic hoses and connections for leaks.

500-Hour Maintenance

- Replace the engine oil and oil filter.

- Replace the fuel filter.

- Inspect the brake system for wear.

- Check battery condition and connections.

1,000-Hour Maintenance

- Replace the hydraulic oil return filter.

- Replace the pilot line filter.

- Replace the travel motor gear oil.

- Replace the air cleaner element.

- Inspect and adjust engine valve clearance.

2,000-Hour Maintenance

- Flush and replace coolant.

- Inspect hydraulic cylinders and seals.

- Check and adjust boom wear pads.

4,000-Hour Maintenance

- Replace hydraulic oil and clean the suction strainer.

- Inspect and service transmission components.

Final Maintenance Recommendations

Regular maintenance keeps your JLG 600AJ operating reliably. For a full range of JLG parts, explore our extensive JLG parts catalog. If you can't find the part you need, reach out to our parts experts for a custom order.

Popular Models

Sany SY215C Excavator Parts

Sany SY135C Compact Excavator Parts

Takeuchi TL8R2 Compact Track Loader Parts

Takeuchi TL12R2 Compact Track Loader Parts

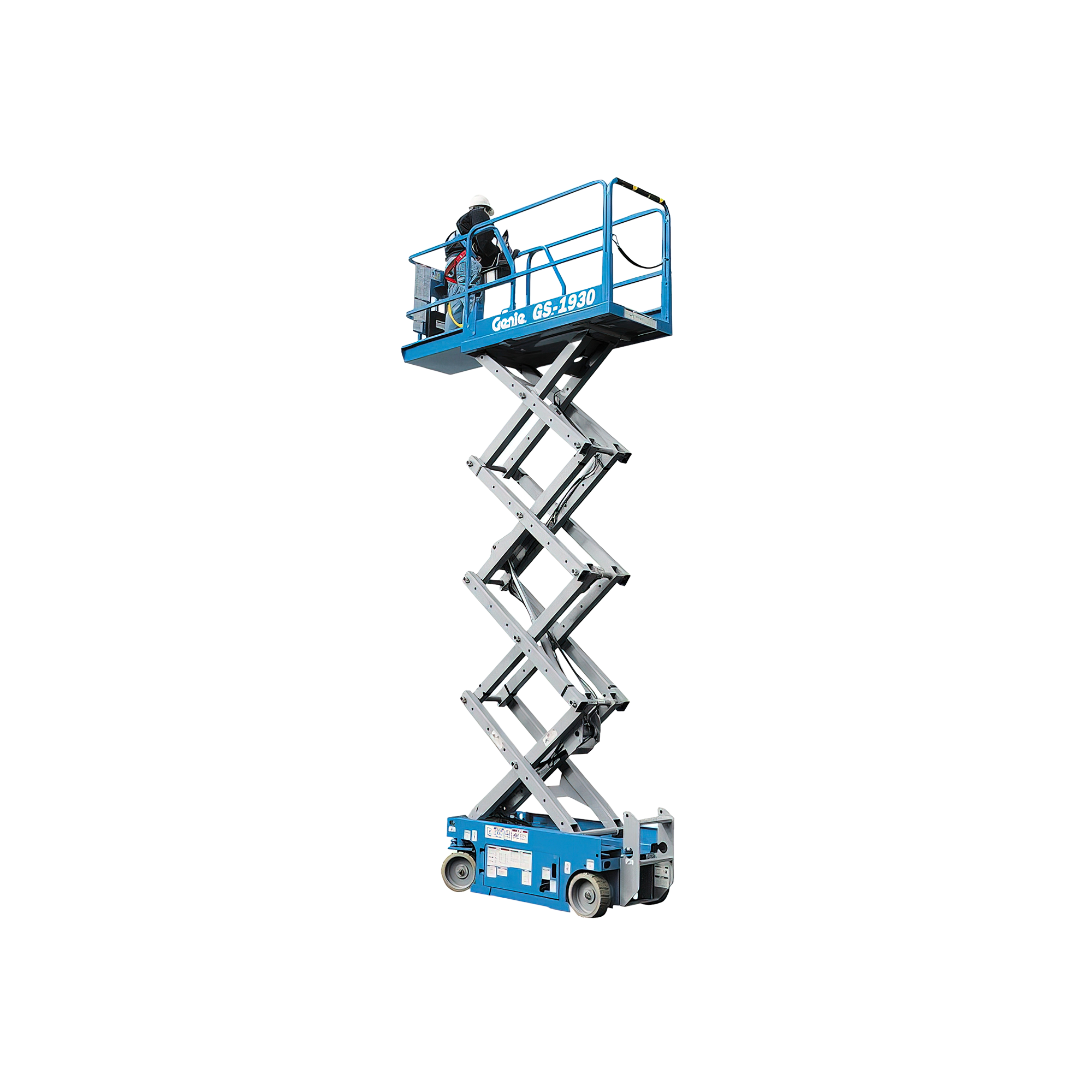

Genie GS-1930 Electric Scissor Lift Parts

Genie GS-2632 Electric Scissor Lift Parts

Skyjack SJIII 3219 Electric Scissor Lift Parts

MEC Micro 19 Electric Scissor Lift Parts

Genie GTH-5519 Telehandler Parts